Big-block engines seem to perform effortlessly well on the street, thanks to the big displacement and big torque inherent to their design. So, when Jake Gibbons of Gibbons Motorsports told Jeff Huneycutt of The Horsepower Monster he was building a big-block for himself, there was next to zero chance we wouldn’t be seeing a video of the project.

Since Huneycutt is a big-block fan, he was incredibly excited to follow Gibbons’ journey to put together a rowdy 598-cube big-block Chevrolet engine for his C10 pickup truck. Originally, the plan for the engine was for something primarily with incredible street manners. However as engine builders are wont to do, the build spiraled to something more aggressive.

The Core Of The Matter

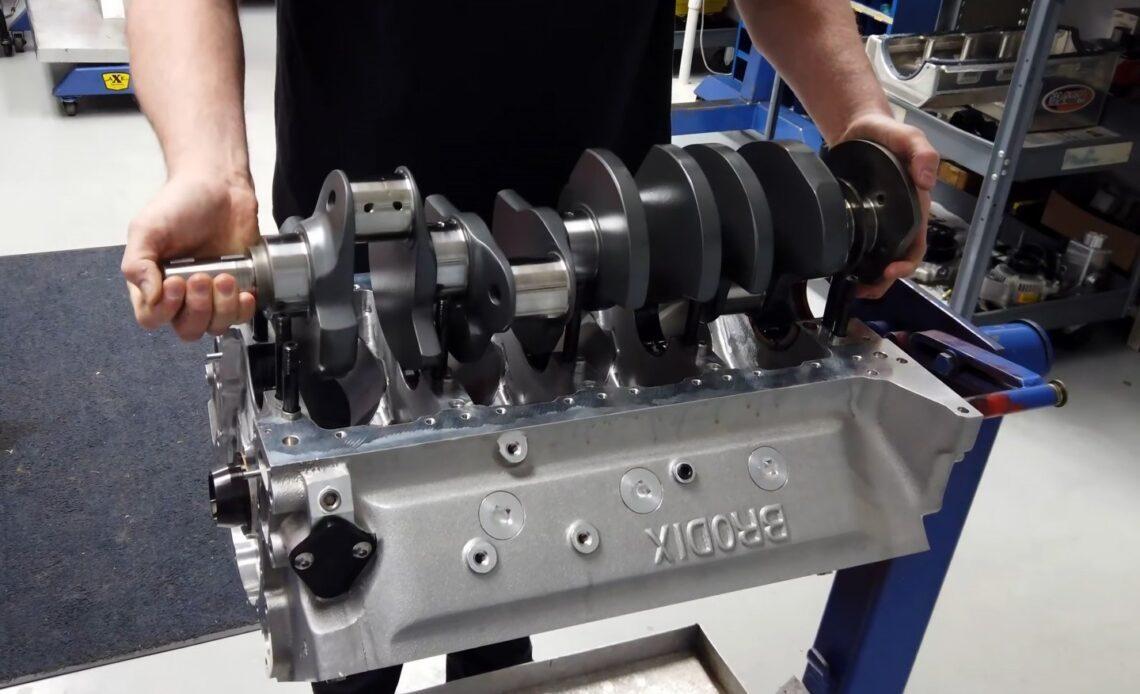

Since part of the goal was a lightweight engine, a tall-deck (10.200 inches) aluminum Brodix block was chosen as the foundation for the engine. However, when the block showed up, it had a larger bore than originally intended, at 4.600 inches. The block’s billet main caps, strengthening webbing, and .938 lifter bores certainly lend themselves to racier parts usage as well.

The crankshaft is a 4.500-inch-stroke forged Callies piece, that is fully counterweighted. Besides profiling the counterweights’ leading edge, the crank has been coated to help shed oil and reduce windage. Clevite coated bearings along with ARP main studs and beefy main cap dowels hold the crankshaft in place. All five main caps are four-bolt designs, but the inner three caps feature splayed outer studs (not bolts).

The fully counterweighted Callies crankshaft will not only be stronger than a six-counterweight design, but will also perform better at high RPM.

Attached to the crankshaft are Molnar forged-steel H-beam connecting rods measuring 6.535 inches, center-to-center. Gibbons took an extra step, sending them to Calico Coatings to be super finished. Clevite coated bearings are used in the rods as…

Click Here to Read the Full Original Article at DragzineDragzine…