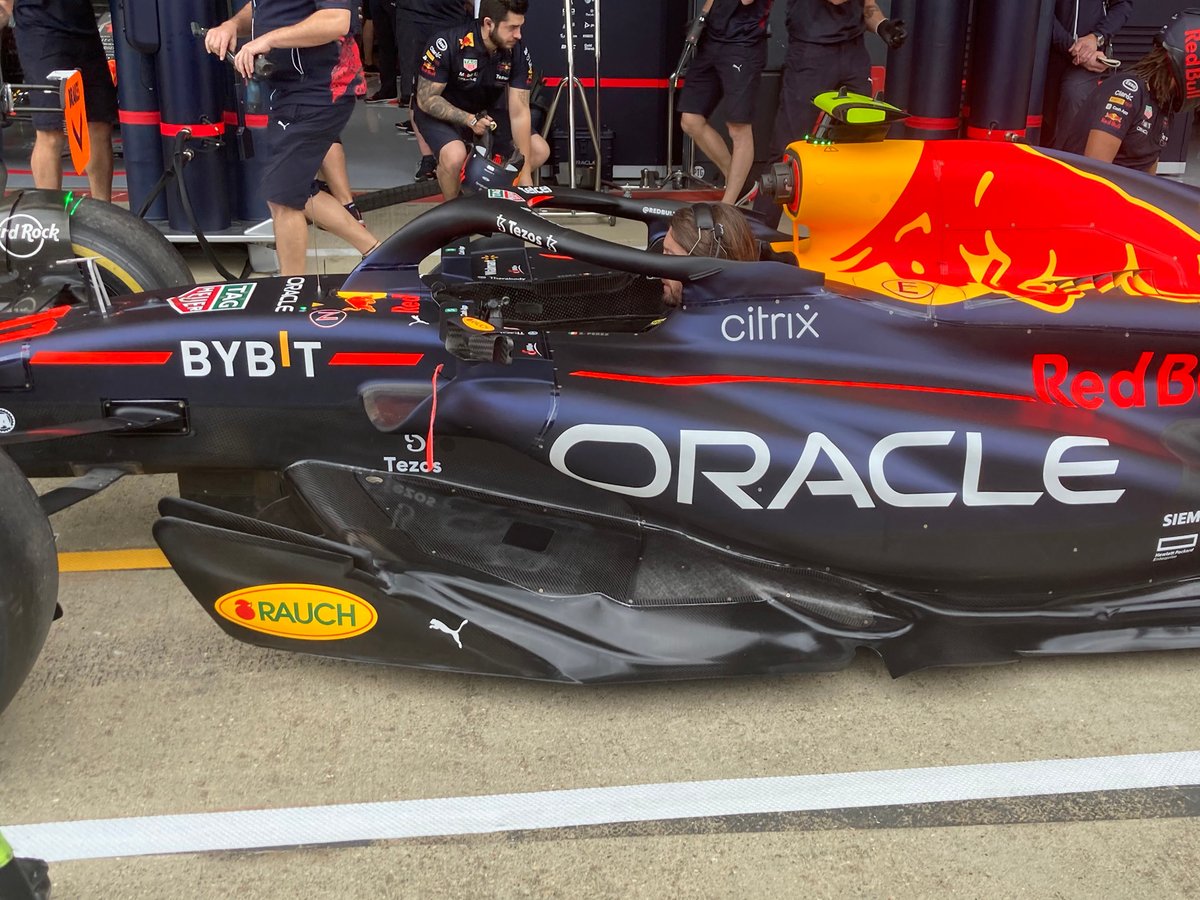

The team has made a significant change to the shape of the bodywork where the sidepods and engine cover meet.

This has created distinctive channels for which the airflow will follow, both over the sidepod and from over the shoulder of the halo.

Interestingly, if we compare it to Red Bull’s sister squad AlphaTauri, it’s somewhat of a kindred spirit with the AT03 which has sported this ‘shelf’ approach since the beginning of the season.

AlphaTauri AT03 rear detail

Photo by: Uncredited

And, just like AlphaTauri, it has resulted in a change to the position of the upper cooling louvre panel, in order that it isolates the heat being rejected from the panel from the airflow passing over the sidepod.

In creating this ‘shelf’, the team has been able to isolate the airflow’s passage over the upper surface of the sidepod.

Plus with the engine cover outlet both being raised and flattened, it provides a much more pronounced undercut into the coke bottle region to enhance performance of the floor and beam wing.

Red Bull Racing RB18 detail

Photo by: Uncredited

Red Bull also continues to optimise its floor package, with revisions made to the strakes and floor edge as the team are on the lookout for small but meaningful ways to improve flow conditions that add up to a net gain across the board.

This is why you’ll see the teams utilise panel sections on the floor this season, in order that they have the agility to make these changes, without needing to re-manufacture the entire structure.

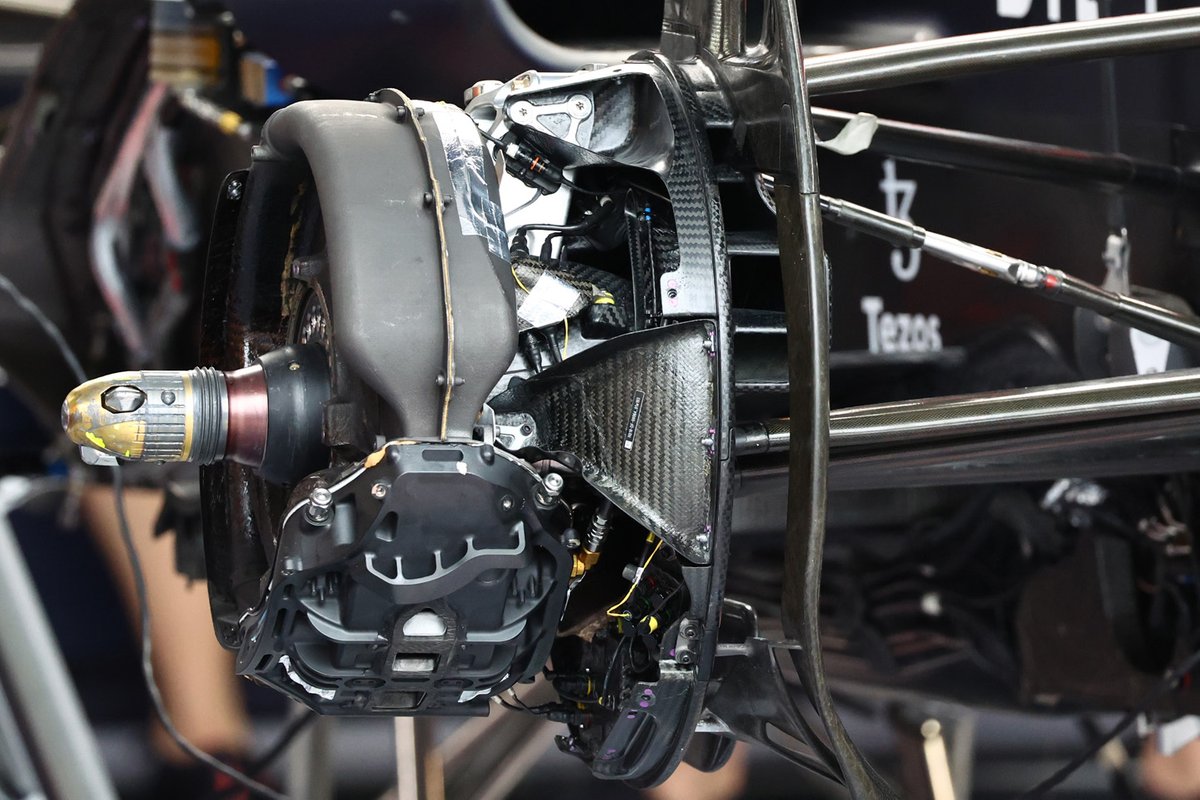

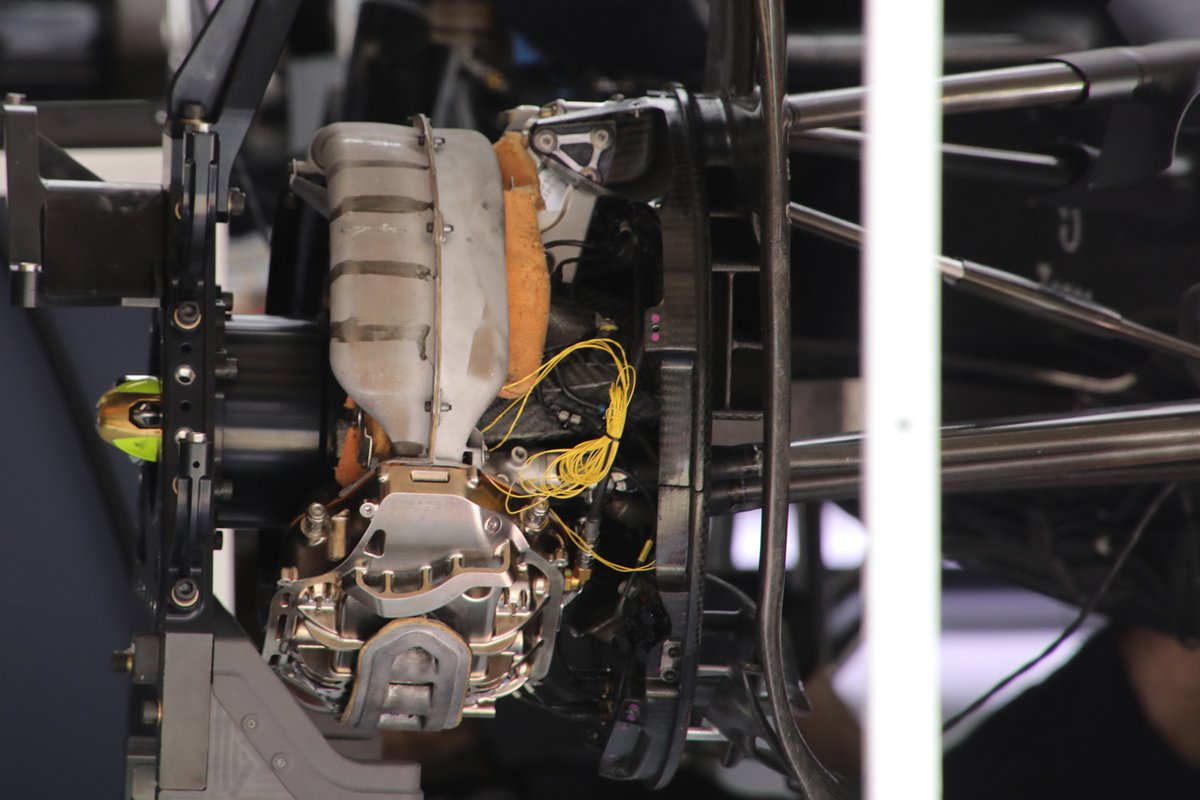

Changes are also afoot with the RB18’s front brake assembly, as the team has revised the design of the caliper in order that it’s not unduly affected by temperature spikes from other components within its close proximity.

This falls in line with the team’s recent addition of a surface treatment on the caliper and brake disc shroud to help manage temperature exchange, with the new coated version on the left, below, and the untreated version on the right.

Click Here to Read the Full Original Article at Autosport.com – Formula 1 – Stories…