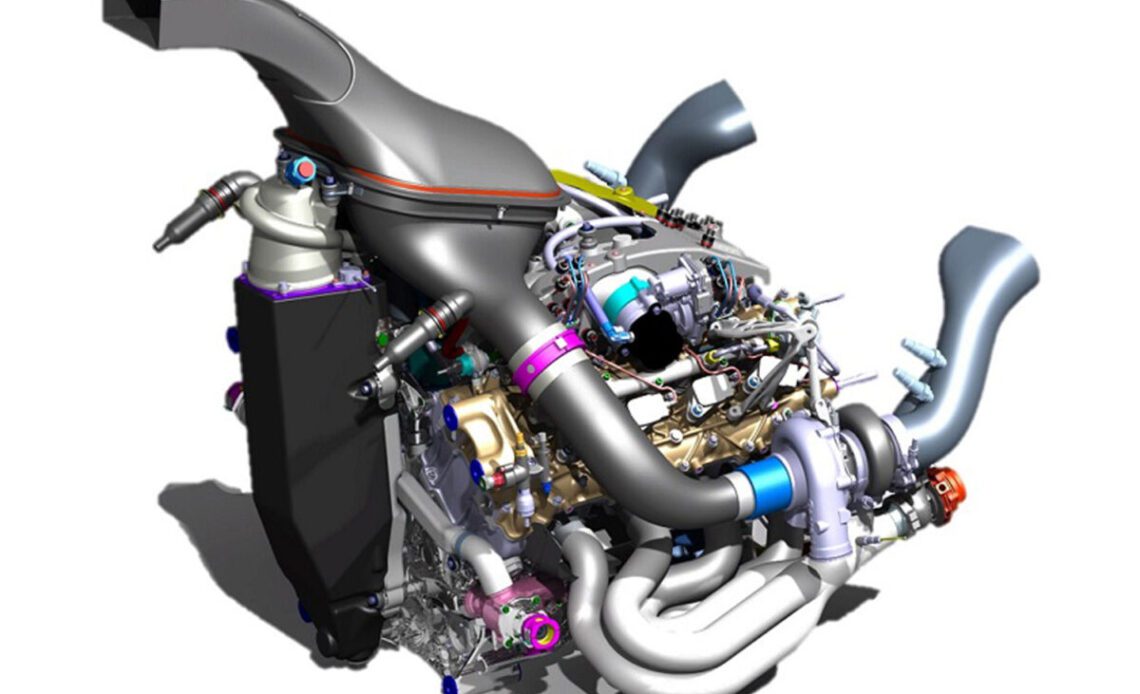

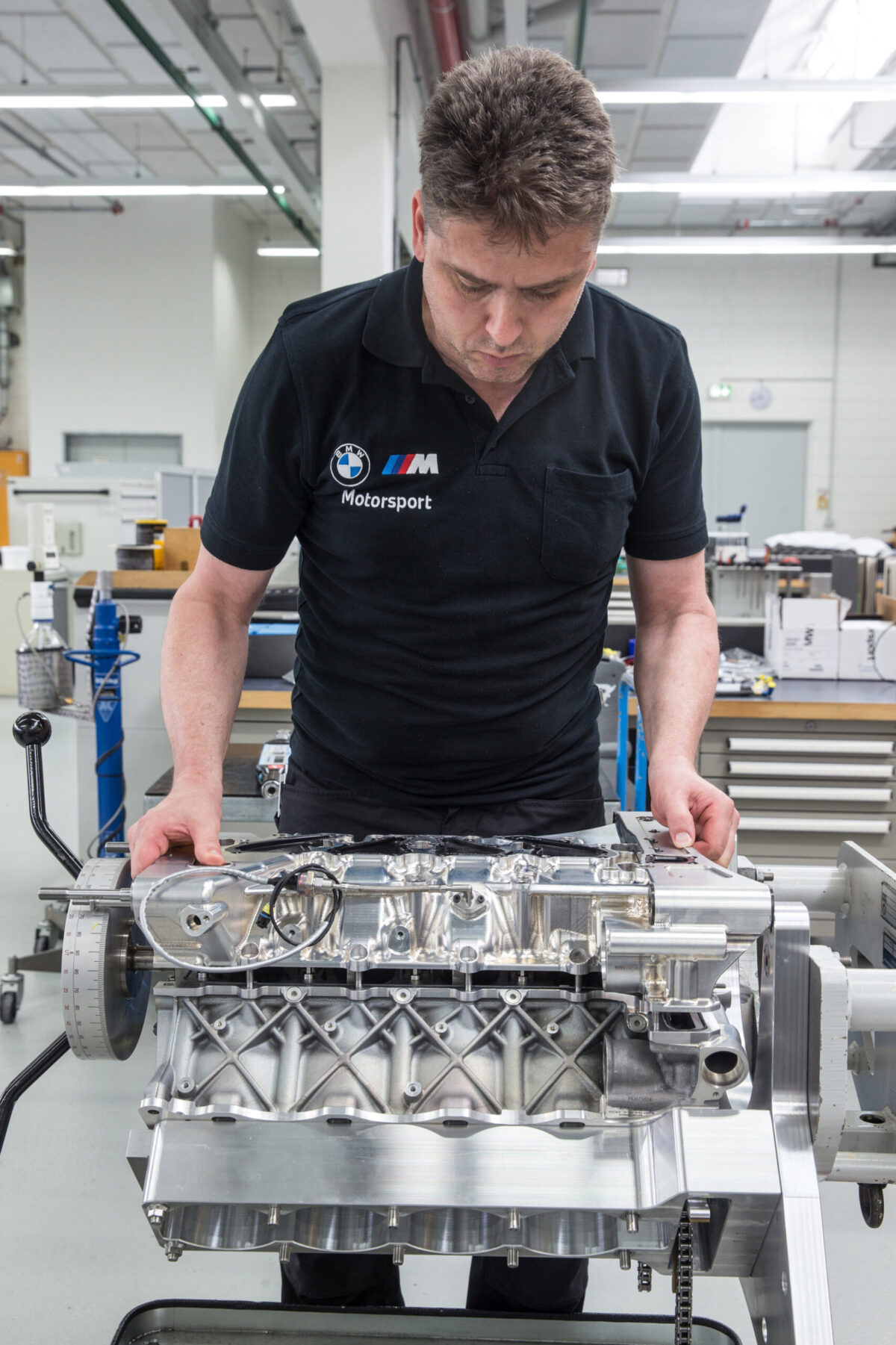

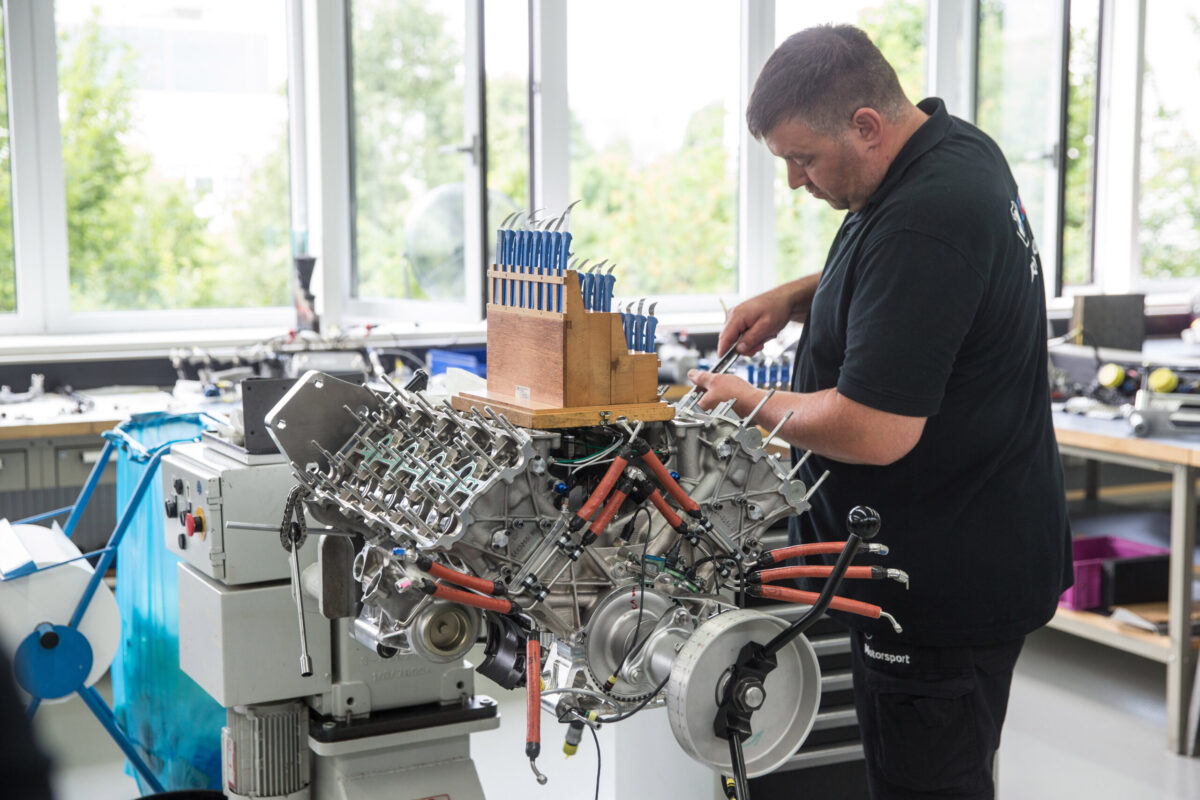

The P66/3 eight-cylinder turbo engine with a supplementary electric drive powers the BMW M Hybrid V8. The combustion engine is based on the DTM unit used in the BMW M4 DTM in 2017 and 2018. During two phases of reconstruction, it underwent comprehensive adjustments to meet the stringent requirements of the LMDh hybrid drive system.

Ulrich Schulz, Head of Drivetrain Design at BMW M Motorsport, and his group had initiated an evaluation to determine which race engine would be best suited for conversion into a high-performance hybrid drive system, even before the BMW Group Board of Management had given the green light to the BMW M Motorsport entry in the LMDh category in June 2021. Time constraints and the need to consider sustainability aspects play an ever more critical role in motor racing and the automobile industry, in general, meant that returning to the drawing board to design a completely new engine and building it at great cost was not an option. Consequently, the question was to establish which proven race engine would best meet the stringent requirements and specifications of the LMDh regulations.

The normally-aspirated P66/1 eight-cylinder engine used in the 2017 and 2018 seasons in the BMW M4 DTM was the one that got the nod. The BMW M Hybrid V8 is a fully load-bearing component in the monocoque chassis without an additional subframe. It was also the one that most closely corresponded to the regulatory requirements after conversion to a hybrid turbo engine.

The normally-aspirated P66/1 eight-cylinder engine used in the 2017 and 2018 seasons in the BMW M4 DTM was the one that got the nod. The BMW M Hybrid V8 is a fully load-bearing component in the monocoque chassis without an additional subframe. It was also the one that most closely corresponded to the regulatory requirements after conversion to a hybrid turbo engine.

‘During the evaluation phase, we also took a look at the P48 four-cylinder turbo engine from the BMW M4 DTM and the P63 eight-cylinder turbo engine from the BMW M8 GTE, but potential problems with the durability of the P48 and the heavy weight of the P63 were negative considerations,’ is how Schulz explained the decision to choose the P66 engine.

‘It is a huge plus that we were able to use existing materials such as steel and aluminum from BMW’s time in Formula 1 for the basis of the engine, as well as for individual components – like shafts, housing, and small parts. That saved us time and money and was efficient and sustainable. Efficiency is a critical factor for this project, as we had a very short period available between getting started and the first racing appearance at Daytona in 2023. Converting the normally-aspirated P66/1 engine into a bi-turbo and then working with the electric drivetrain colleagues to turn it into a hybrid drive system was very complex.’

The…

The…

Click Here to Read the Full Original Article at Racecar Engineering…