Automotive rearend designs can effectively be categorized into two groups. The first design is the removable center section design, which groups the ring-and-pinion, third-member, and center carrier bearings independent from the housing. The second is a complete rearend housing design that contains the differential assembly components within the rearend itself.

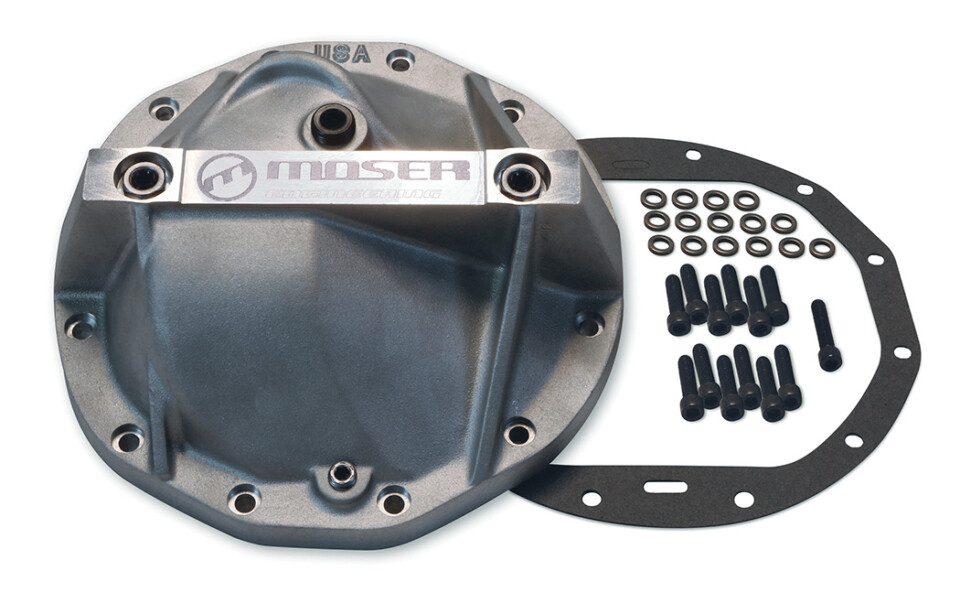

Without modifications to the housing style design, Moser Engineering’s performance girdle adds strength to the overall housing, because the covers are made from thick 356-T6 aluminum. The included cover bolts are torqued to specification, adding a “boxing” structure support to the overall housing.

Another benefit is two load bolts that have a special significance; they are adjusted to ride against the pair of bearing main caps inside your housing. These load bolts are torqued against the backside of the carrier’s main caps. This cover prevents deflection of these caps under acceleration to improve ring-and-pinion gear life and the rearend’s overall strength.

This view from inside the Moser cover shows the two load bolts that have a wide contact face to brace against the bearing caps. These are torqued to 5 ft-lbs maximum. Over-torquing could result in distortion of the caps.

With the large access opening behind such rearends as the General Motors 12-bolt, the Dana 60, and the 8.8 Ford, this back opening design can hamper gear life under extreme loads. Bracing your bearing caps with the Moser girdle/cover significantly reduces ring gear deflection and deflection oddities across the entire differential area of the rearend while under the drivetrain shock of your launch, as well as your overall acceleration.

Another advantage of using the Moser cover is the drain and fill access points incorporated into the cover. These fluid access points allow faster and easier rear differential gear oil servicing by eliminating the need to completely remove the cover.

Moser Engineering has you “covered” by implementing their heavy-duty performance girdles for many popular rearend housings exposed to big acceleration stress factors.

Click Here to Read the Full Original Article at DragzineDragzine…