In earlier days of motorsports, most racing and performance engines were repurposed from “factory” manufactured engine blocks. Massaging and machining these OEM blocks was an effort to strengthen them for ever-growing cubic inches and horsepower output.

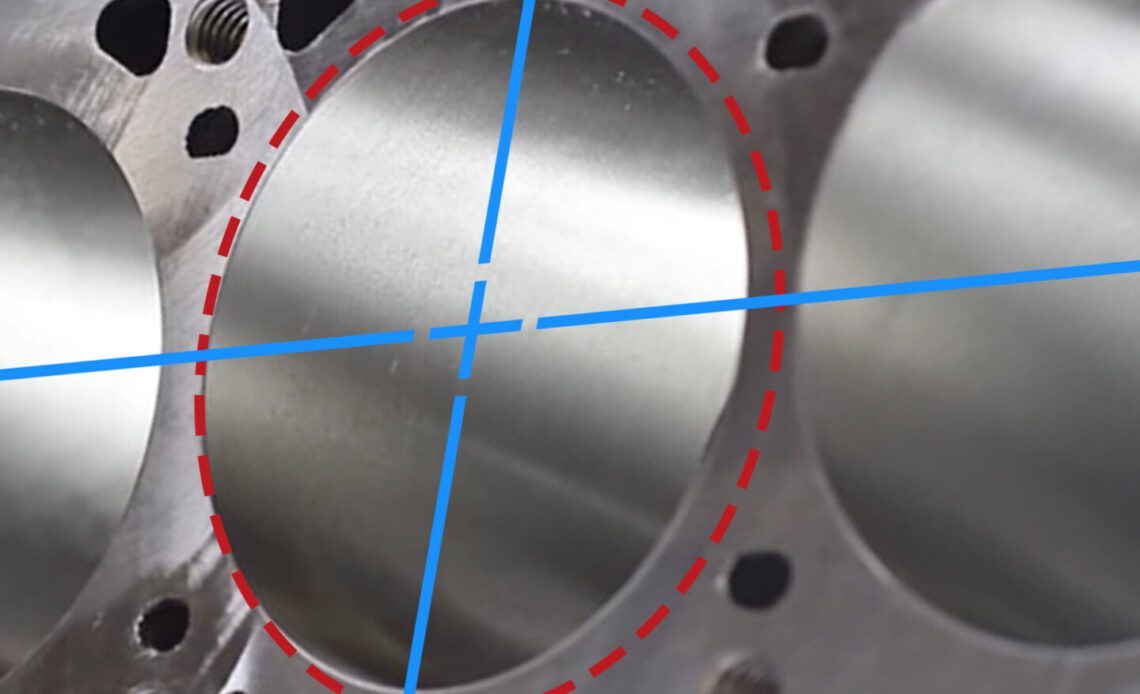

When the inner block casting mold is shifted compared to the outer mold, the most detrimental outcome is uneven cylinder wall thickness.

World Products is an industry leading company that grew from the idea of providing dedicated block designs that never started life as a truck engine block or similar. One of the key advantages of a World Products engine block is the effort to prevent core shift.

Core Shift Explained

Nitro racers in the 1960s would search factory Hemi engine blocks to find those few whose inner water passage dimensionally matched the outer casting location. The “core shift” happens when the internal molds shift in relation to the outer mold as the mold was filled with molten iron.

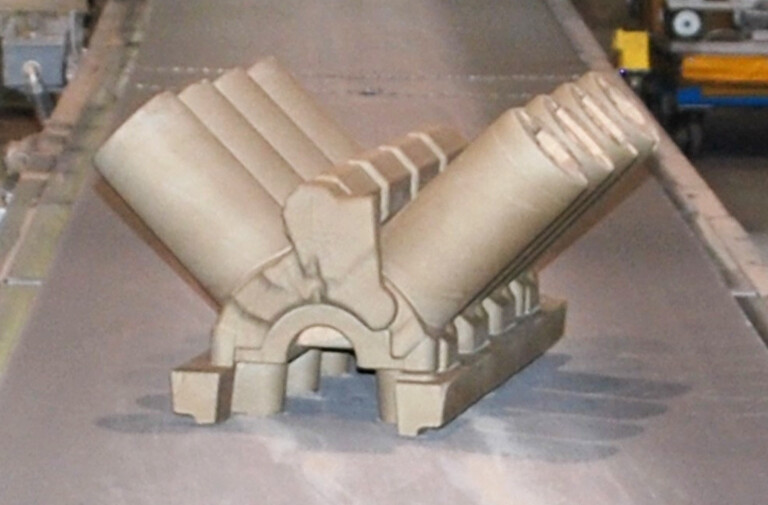

A block’s inner mold once consisted of individual sections that were stacked for casting. World Products uses new technology to create an entire inner mold preventing internal shift.

The most obvious effect of core shift is cylinder wall thickness. If the outer cylinder wall at the cooling passages shifts, the dimension of the inner cylinder face would be thick on one side, while the opposite is dangerously thin. This problem was not a concern for mass-produced blocks for the family station wagon. Historically, blocks with core shifts would split over bored cylinder walls and/or flex, attributing to cam, crankshaft, and other component failures.

Better Casting Accuracy

World Products resolved core shift issues using a one-piece major core design which greatly increased casting stability. This new design combines all eight cylinders, cam tunnel, and main bearing saddle in one central core, eliminating dimension variations.

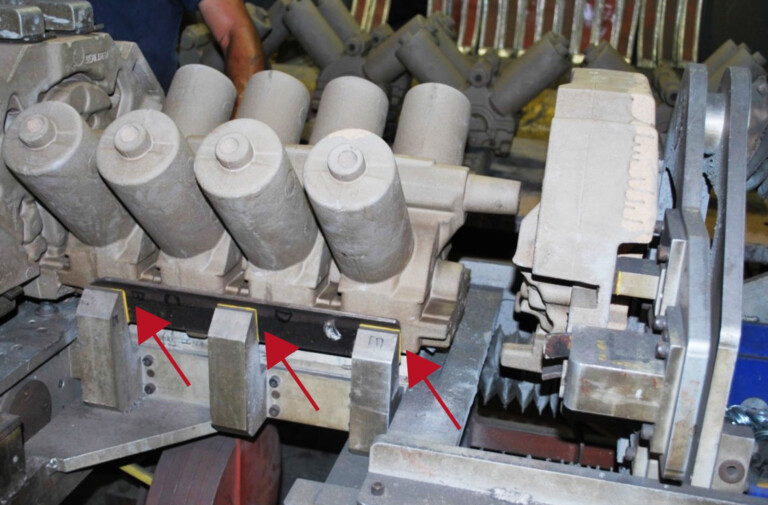

In earlier days, the machinists only had a point from colored marker to center their machining. Today, the sturdier molds are cast with fixture points (arrows) to properly align a block between the casting and machining facilities.

Attributed Machining Accuracy

This new casting process also offers higher accuracy when the block is moved to the machining processes. The new one-piece core design also includes fixing points within the engine block’s pan rail. These indicators in the casting provide exact starting points to correlate the machine work to the inner casting locations…

Click Here to Read the Full Original Article at DragzineDragzine…