Top Secret

Kakuda would not be drawn to expose the details of the changes, calling them ‘top secret’. However, he admits that ‘we explored many different paths in developing this area and tried many different configurations. We have also developed very accurate simulations to prove our concepts before implementing them into a mechanical system.’ The RBPTH001 takes advantage of a significant amount of additive-manufactured (AM) parts. Kakuda emphasises the fact that additive manufacturing allows engineers to create components with the structure only where load transfers through the part, which is obviously efficient.

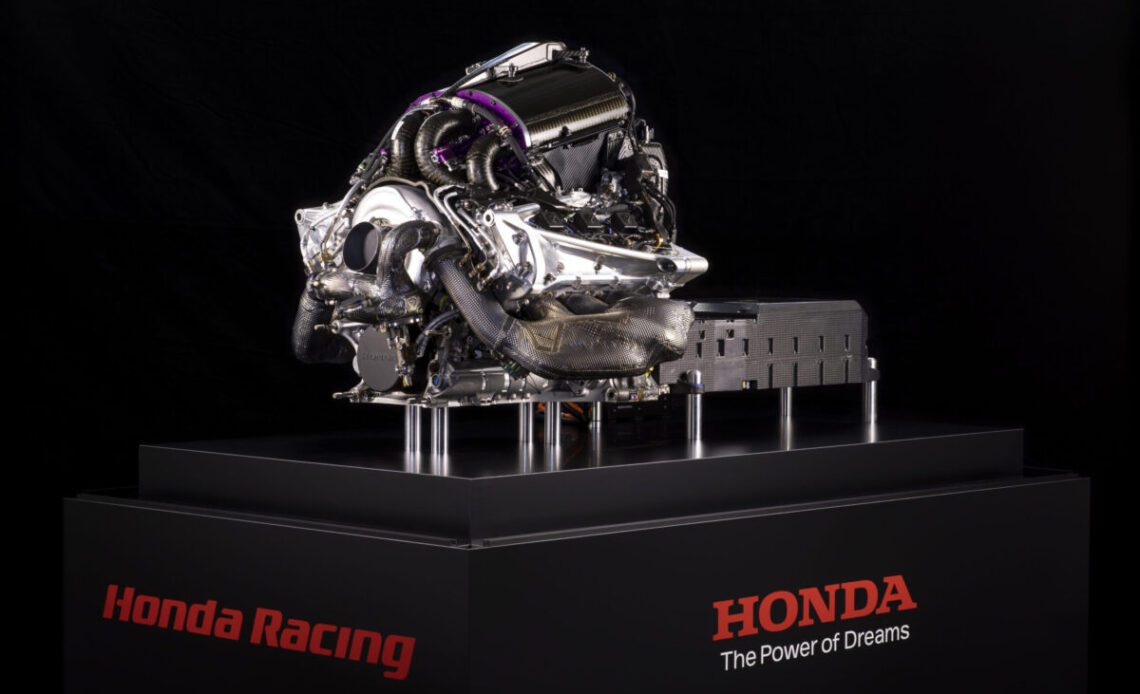

‘Additive manufacturing has allowed us to optimise many components, including pistons and the turbocharger housing,’ he says. ‘Although Formula 1 has many restrictions on the materials teams are allowed to use, we have tried many different materials and combinations that fit within the regulations to give us the performance we want for our additive manufactured components.’ Honda also adjusted the crankshaft and cylinder block geometry to ensure reliability with the new E10 combustion conditions, while a specialised cylinder liner coating was applied at Honda’s Kumamoto factory. ‘We developed the whole combustion loop to exploit E10 in the most profitable way, including the injection system, exhaust system and turbocharger compressor and turbine efficiencies,’ Kakuda notes.

‘The RBPTH001 power unit weighed more than the RA621H [2021 version] thanks to beefed-up components to aid reliability, but the dimensions are almost identical in terms of the outside shape and volume. ‘However, several points of the chassis installation are different. For example, the exhaust and intake pipework and the electrical system loom layout.’

Close collaboration

Of note is the fact the RBPTH001 power unit was not solely a Honda F1 department venture. The broader Honda company was involved in various activities. The Honda aircraft division, which developed the HF120 turbofan engine in conjunction with GE, the motorcycle division and the automotive division assists wherever necessary. ‘If the F1 division would like expertise from any others then the working relationship is there, and vice versa,’ Kakuda explains. ‘We collaborated closely with the jet engine division to develop our compressor and turbine for the Formula 1 project.

‘The jet engine division also has very efficient and precise manufacturing processes that we…

Click Here to Read the Full Original Article at Racecar Engineering…