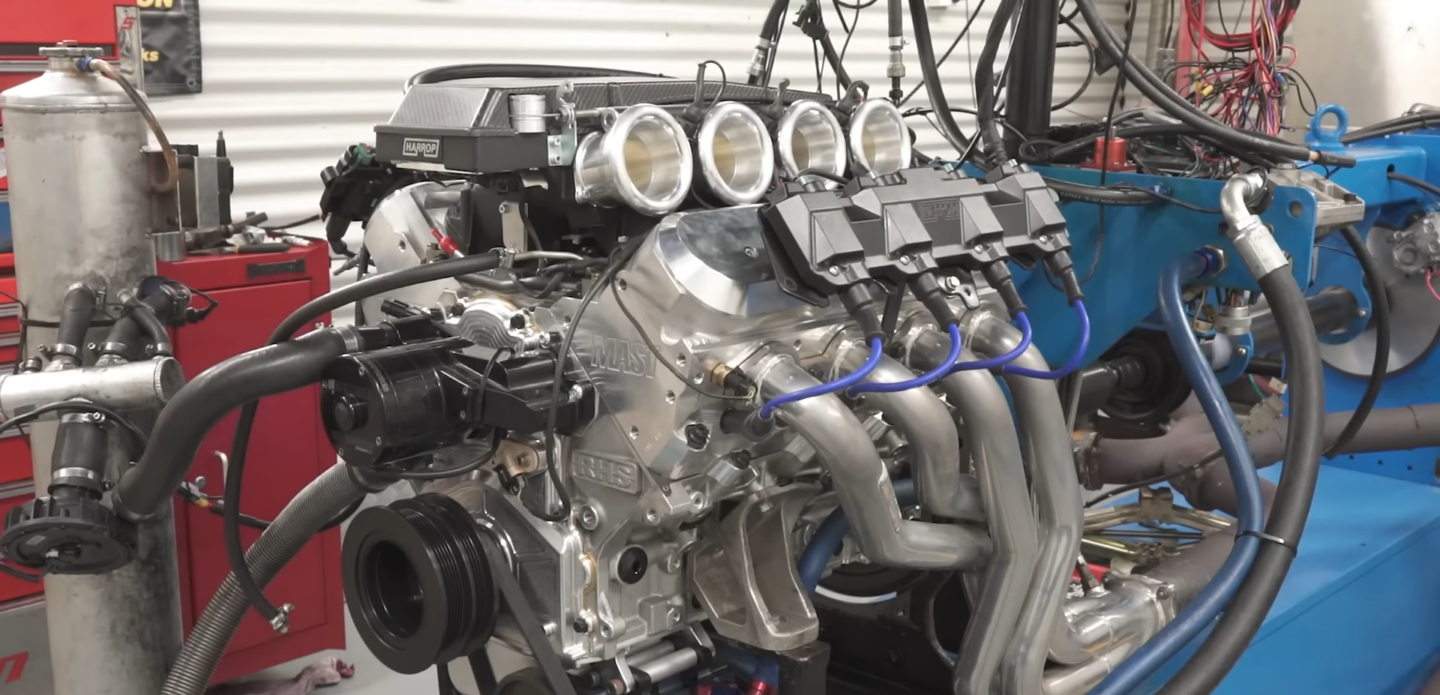

As car lovers, we can’t help but enjoy the wine of a supercharger bolted atop a V8. Unfortunately, unless you are a do-it-yourself type, you will not likely get to see what goes into building a high-horsepower blower engine. But, not to worry, Heath Moore from Harrop Engineering gives us a look behind the curtain at Mast Motorsports and shows us a supercharged L8T making four-digit horsepower.

Moore recently made his way to the States to visit the Texas-based performance parts manufacturer. Mostly known for its high-performance cylinder heads, Moore received a tour of Mast’s manufacturing facility from none other than Horace Mast to see firsthand the process of creating LS and LT heads to meet customers’ needs worldwide. Fortunately, there was a Harrop-supercharged L8T on the engine dyno during the tour as well.

Engine packages like this Harrop-supercharged L8T have become a large part of Mast Motorsports’ business and are an excellent way for them to show off what their cylinder heads are capable of.

Although development initially centered around the Gen IV LS, Horace explained Mast Motorsports is investing in newer platforms like the Gen V LT and remaining heavily focused on engineering innovations in all its cylinder heads. In addition to developing and manufacturing high-performance heads, Mast offers its customers complete engine packages.

An expertly crafted cylinder head from Mast Motorsports is ready to handle anything Harrop’s superchargers can throw at it. Need a pair of heads to handle 1,000 horsepower? No problem.

In the workshop, the air is filled with familiar sounds of CNC machines whirring and tools running, the sweet symphony of high-performance parts in process. The metal shavings fly around the clock as cylinder heads are machined in various stages. Mast offers a large variety of heads to choose from, with 14 currently for the LS platform, not including race-specific heads, and more to suit a variety of other engines. One advantage of Mast’s heads is their durability and build quality. Thanks to their thick decks, a supercharger can run at its full potential with minimal compromise in water flow and cooling effects throughout the heads.

Mast Motorsports can build you a naturally aspirated or boosted engine combination. Check out this LS7 with a Harrop ITB intake manifold and Mast Black Label cylinder heads.

The R&D teams at Harrop and Mast continue to push the envelope of innovation, with 1,000-plus horsepower being the…

Click Here to Read the Full Original Article at DragzineDragzine…