LS-based engines have proven themselves worthy time and time again as the king of the modern junkyard engines. You’ve heard the wild tales of the immense horsepower these mills can make straight out of the boneyard, but there are some steps you should take if you want one of these engines to last.

If you want to build a truly reliable LS-based engine from a junkyard, you’ll need to take the parts to a machine shop for inspection and proper prep. Sure, there are people out there who’ve done some amazing things with these engines without going to a machine shop, but that’s a big risk. These engines have been through a lifetime of use before a high-performance enthusiast harvests them for a project.

If you don’t have these types of machines in your home shop, chances are you’re not going to be able to truly prepare an engine properly for assembly.

We took the 5.3 aluminum LS block, OEM 243 casting cylinder heads, and Summit Racing’s Summit Pro LS rotating assembly for Project Swedish Meatball to Craig Haslem at RPM Engine and Machine so it could be prepared for assembly. In this article, we’re going to cover why it’s a good idea to take your junkyard treasures to a machine shop before you start throwing all the boost at them.

Block Party

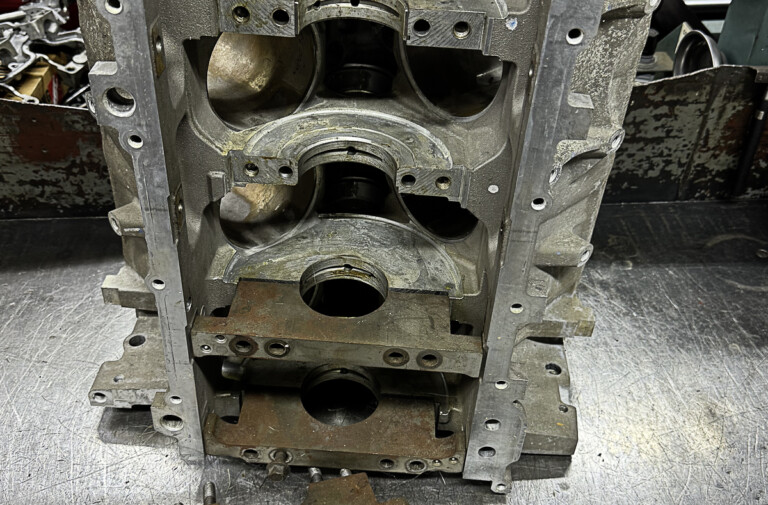

The engine block is the foundation of the build, so you need to make sure the foundation is solid before you begin. A junkyard engine block can hide plenty of problems under grime and rust. The first thing a shop is going to do is deep clean a block so it can properly inspect it. The shop is going to look for cracks, bad bolt holes, and threads that need help.

Our block was dirtbag dirty before Craig worked his magic to make it look better-than-new.

Being precise prevents problems. Haslem explains why a shop is better equipped to do these tasks the right way.

“You could do the old eyeball test at home after cleaning the block up, but that doesn’t guarantee you’ll catch everything. At the shop, we are going to be able to make sure every surface is perfectly flat and all of the holes are problem-free. What happens if you do find a problem with the block at home? Most people just don’t have the right equipment to correct issues like resizing cylinder bores and so on.”

After the block has been properly cleaned, the shop can look it over for any issues. The shop will then make sure all the holes are ready for fresh hardware and also get the mains ready for machine work.

When you instruct the shop to…

Click Here to Read the Full Original Article at DragzineDragzine…