If you are looking to get the most power potential possible from your camshaft, whether it’s a simple cam swap or a complete engine rebuild, properly degreeing a camshaft is a crucial step. By ensuring a proper relationship with the crankshaft, you ensure that all your valve timing events are happening exactly when they are supposed to, and your camshaft is operating at its fullest potential.

When installing a camshaft, you need to ensure that its relationship to the crankshaft is degree-perfect. While some people will just line up the dots on the cam and crank gears and call it good, in most cases, good enough, isn’t. Manufacturing involves acceptable tolerances, and with the number of intricate parts in the valvetrain, it doesn’t take much of a tolerance stack to really throw things off. So, we verify everything is as it should be through camshaft degreeing.

The Right Tools For Degreeing a Camshaft

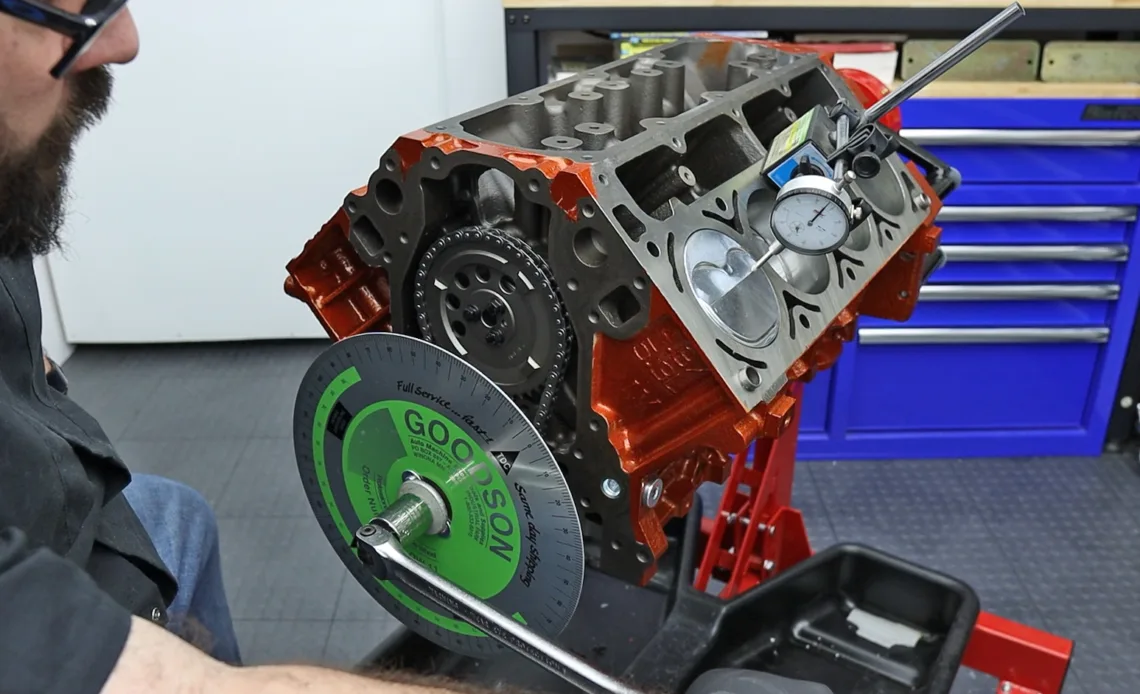

To degree your cam, at a bare minimum, you’ll need a few simple tools: A basic degree wheel, a dial indicator with a magnetic base, and some sort of pointer. Now, the pointer can be as simple as a piece of coathanger wire bent to shape. You can get super fancy (and expensive) with all of the tools needed to degree a cam, but you can get accurate readings with the simplest versions of them with a little care.

For this exercise, we are using a Goodson degree wheel kit (P/N: DW-KIT-2). The kit comes with an 11-inch-diameter degree wheel, along with a centering hub and sleeve kit allowing it to be mounted directly to a crankshaft with the balancer bolt. We are also using a simple, inexpensive 1-inch dial indicator and magnetic base available from any hardware store. Finally, we are using a piece of wire with a loop on the end designed to be bent into place for our pointer.

These are the basic tools needed to degree a cam: a degree wheel (left), a dial indicator and magnetic base (center), and a timing pointer of some sort (right). There are fancier and more expensive options of each, but these will get the job done with a little care.

Truing Up The Degree Wheel

The first step in degreeing a camshaft is to true up the degree wheel. With the timing set adjusted to zero degrees of advance or retard and the degree wheel bolted to the crankshaft, you need to set piston number one to Top Dead Center. We use a dial indicator to find that, which allows for a few degrees of dwell as the crank…

Click Here to Read the Full Original Article at DragzineDragzine…