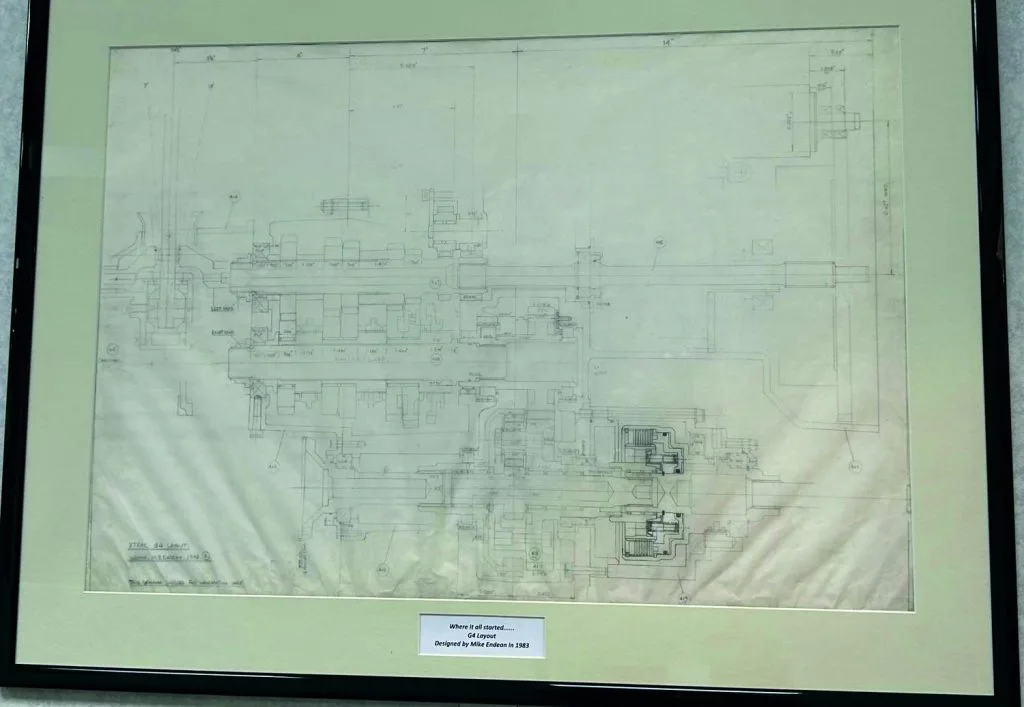

Each day, employees entering Xtrac’s design office pass a wall-mounted layout drawing for the company’s first racecar transmission. The G4 gearbox was developed by former Hewland engineer, Mike Endean, for rallycross star Martin Schanche’s four-wheel-drive Ford Escort. The plan serves as a reminder of where Xtrac started, and how much it has grown in the 40 years since. Now entering its fifth decade, the British transmission manufacturer has an increasing staff count of almost 500 employees, two build shops in the United States and several long-term supply deals for major series.

It currently builds the gearboxes for IndyCar, NASCAR, Supercars, all LMDh cars, most LMH cars, several in Formula E and more. In recent years, Xtrac has diversified into the high-performance automotive sector with electrification projects and boasts an impressive factory in the UK. Racecar recently went to Thatcham to find out what 40 years of progress looks like.

Xtrac: Origins

The first Xtrac headquarters were as humble as you like: a small workshop around the back of a Chinese takeaway in Wokingham, a small town west of London. Endean built transmissions and related components in small quantities, mostly for off-road motorsport. The name Xtrac only emerged after Endean’s G4 gearbox had started racing in 1983. The story goes that Endean light-heartedly told the revered British motorsport commentator, Murray Walker, that his as-yet-unnamed firm could be called ‘Mr X’s Traction Company’. Walker then ran with it, going onto the broadcast and shortening it to ‘Xtrac’. The impromptu, catchy moniker stuck and Endean, together with his wife, Shirley, established Xtrac Ltd on June 15, 1984.

Building on its success with Schanche, Xtrac gained more off-road customers, particularly manufacturers building cars for the Group A regulations. As it gained more work, Xtrac moved to a new 9000ft.sq factory at Hogwood Lane, having moved out of the cramped workshop behind the takeaway.

‘We were bringing in one new person every two to three weeks,’ recalls Peter Digby, Xtrac president and one of the company’s earliest employees. ‘We couldn’t afford to buy machines because we were so small, so we would go to these [car manufacturer] customers and say, if you want to have that gearbox, we need this much up front for design, tooling etc.’

As the company grew in the late ’80s, bringing more processes such as heat treatment in-house, it branched out from…

Click Here to Read the Full Original Article at Racecar Engineering…