We’ve brought you a number of articles on fasteners — head bolts in particular — how they are made, and when to use them. We’ve also talked to you about different fastener materials and what their benefits are over each other. But, like you, we like to see, rather than just talking about it. Luckily for us, the Torque Test Channel exists and they take “showing” to a whole new level.

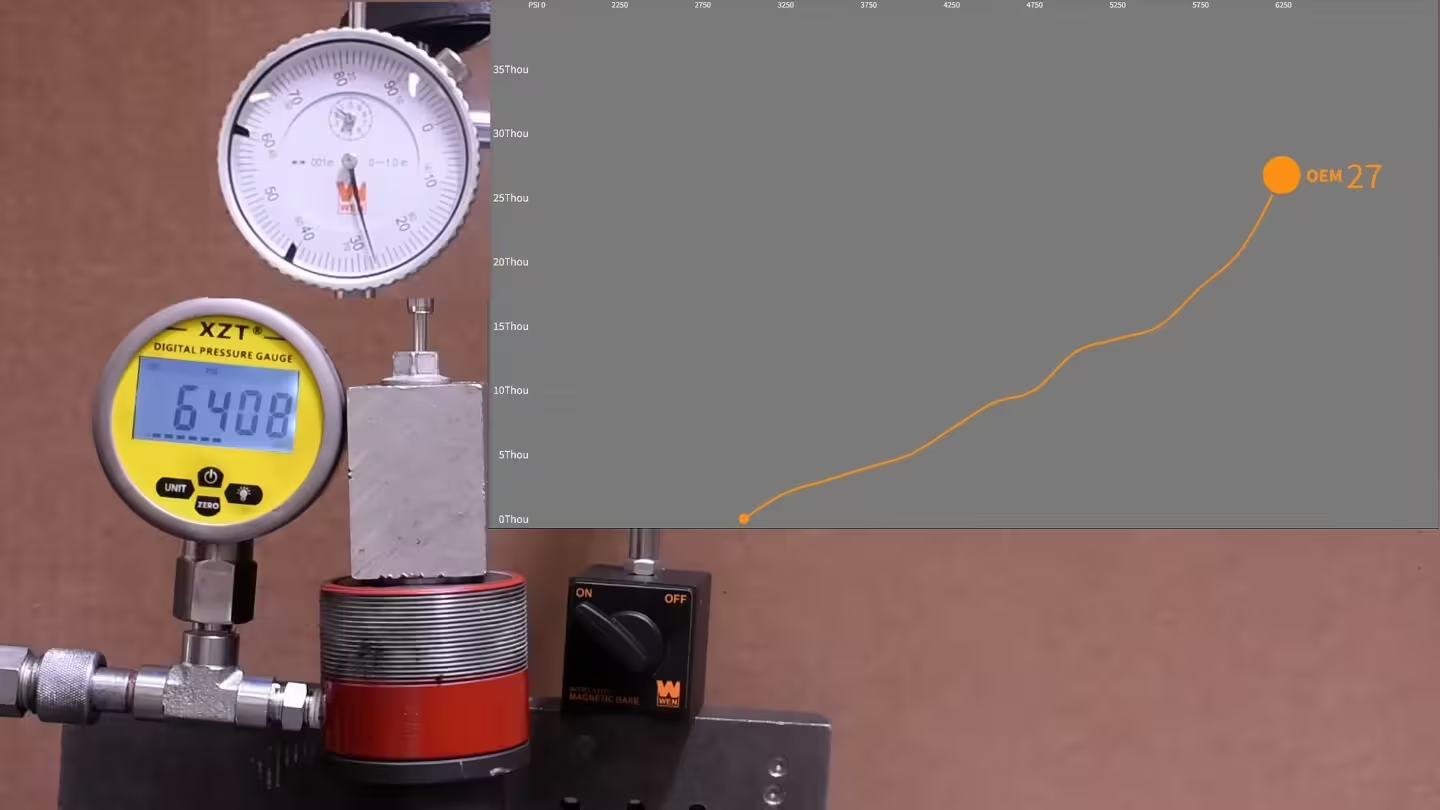

Instead of just saying “ARP 2000 has a higher tensile strength than a standard 8740 steel fastener” and showing a chart, they built a test rig that measures both the clamping load provided, as well as the actual fastener stretch, in real-time. Besides providing cool footage (and killing dial indicators by the gross) testing each fastener to failure gives a clear idea of the capabilities (and weaknesses) of the different fasteners they are testing.

To be clear, this is not a test about overtightening bolts, but rather the TTC team took extraordinary steps to ensure a proper analog to a typical LS engine block and cylinder head configuration. The team then torqued each test sample in the proper torque sequence according to each individual product’s instructions, with proper thread lubrication applied.

The additional load to bring the fastener to failure comes from a single-action hollow ram hydraulic cylinder, capable of providing 24,000-plus pounds of force on the test apparatus. By bringing the fastener and rig to the standard condition of an assembled engine, and providing external load beyond the inherent preload, the fasteners are tested in a manner that is as near identical as possible to the way a cylinder head fastener is stressed in the real world.

Make sure to watch the video in full, as we’re not going to spoil the results in the article. But we can tell you the list of fasteners includes multiple OE-spec torque-to-yield head bolts, 8740 bolts and studs, ARP2000 bolts and studs, L19 studs, some Amazon-special stud kits, and even a hardware-store Grade 8 bolt just for giggles — I mean scientific comparison.

Carve out the 20 minutes or so to watch the video in its entirety, and not only will you be entertained by the destruction of multiple dial indicators as the fasteners reach their failure points, but also get a solid idea of why upgraded fastener materials are beneficial.

Click Here to Read the Full Original Article at DragzineDragzine…