When your engine has optimal ring seal, it’s going to make more horsepower. There are lots of tricks to keep top rings where they need to be, and using pistons with gas ports is one of those methods. MAHLE Motorsport does a great job breaking down the basics of piston gas ports and why they’re effective.

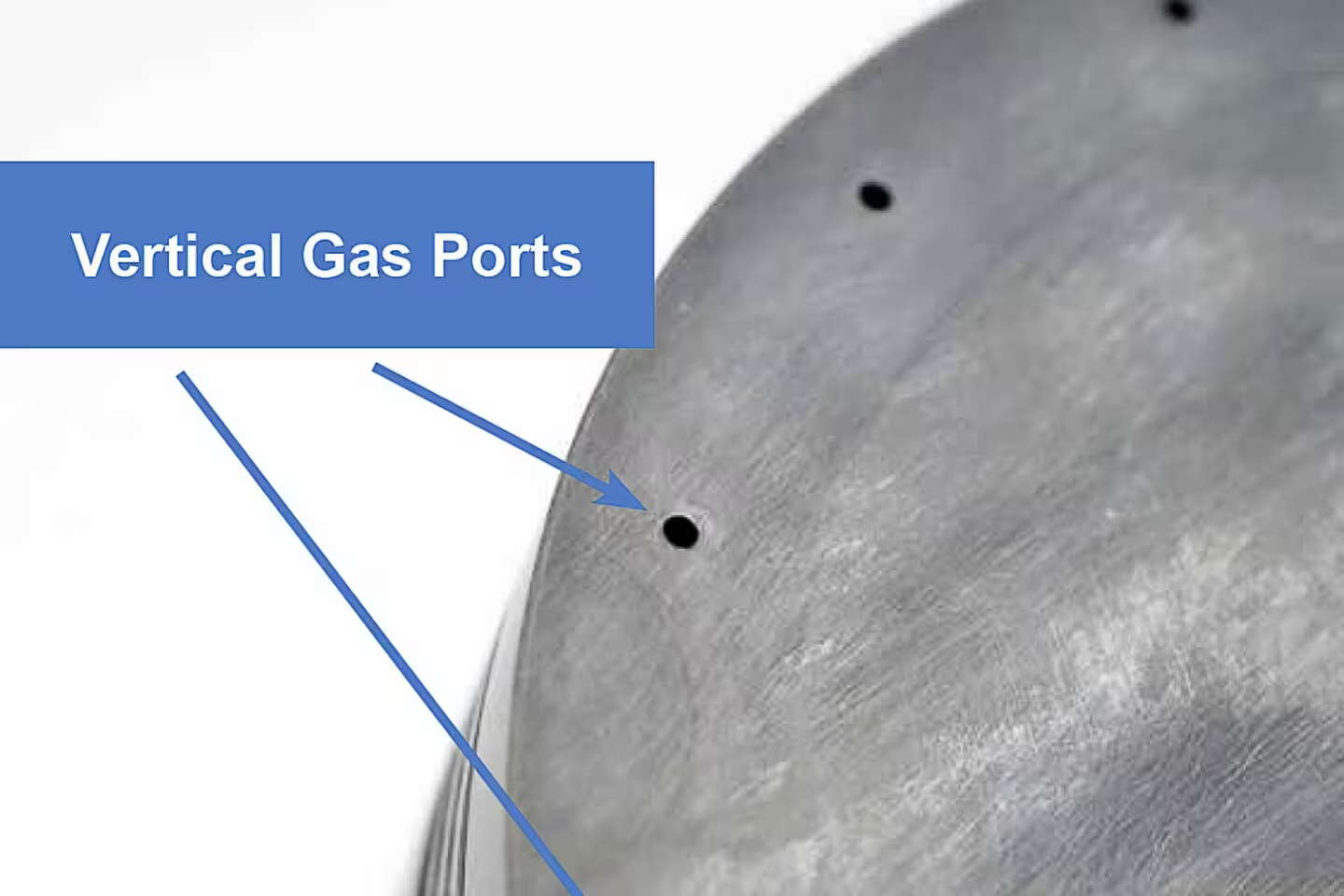

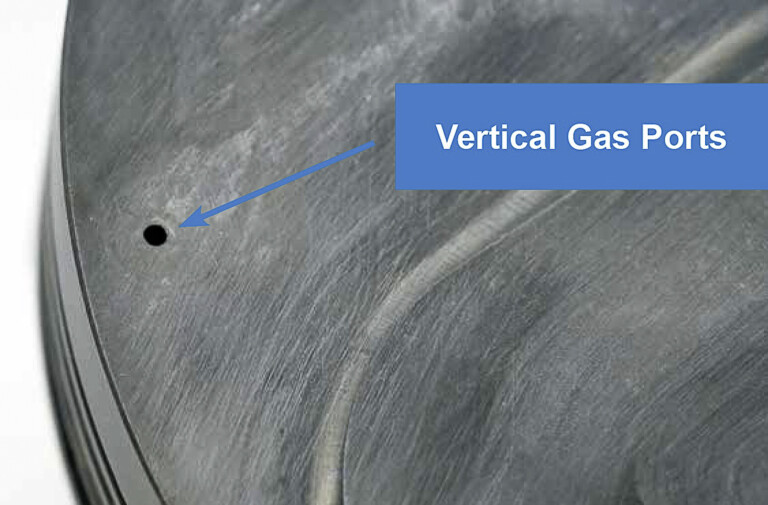

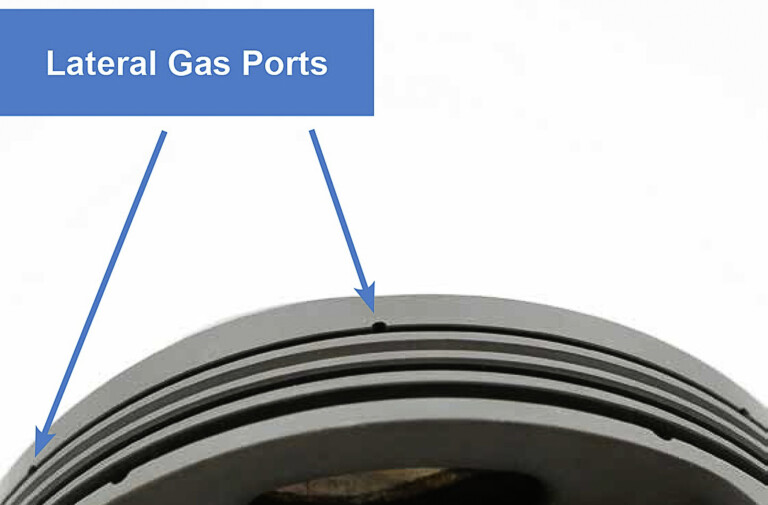

There are two types of gas ports that can be added to a piston, vertical and lateral. A vertical port is added to the top of the piston and has an air shaft that leads to the top of the ring groove. That shaft channels the gas to the ring and pushes it out to increase the ring seal. The lateral gas port can be found along the top edge of the piston with the top ring groove. These gas ports increase the top ring’s seal when since they direct the cylinder pressure behind the top ring. This pressure pushes the ring out and against the cylinder wall, therefore improving the ring seal.

In a recent tech post on Facebook, the team at MAHLE put some great information out there about gas ports.

“Both types of ports allow pressure to get in behind the top ring more easily and push it out against the edge of the cylinder to create a better seal. With the more direct path for pressure to flow, vertical ports are faster at directing pressure behind the ring, but are not used as often due to the high probability of clogging with carbon and combustion residue. Lateral ports are more commonly used, and do not have the same clogging issues as vertical. However, the tradeoff is lateral ports take longer to channel cylinder pressure behind the ring than vertical.”

Clearly, gas ports in pistons are some great advantages. If you’d like to learn more about gas ports and how they can be used you’ll want to reach out to the team at MAHLE Motorsports right here on the company’s website.

Click Here to Read the Full Original Article at DragzineDragzine…