One of the more remarkable aspects of the modern performance era is how stout some of the factory engines are. In the past, you couldn’t take a stock block small-block Chevy and expect it to live pushing near four-digit horsepower under an 8-71 blower pumping in a mix of oxygen and alcohol. But in recent years, modern engines like the LS and LT platforms from GM have been able to do it with the stock block, crankshaft, and heads without breaking a sweat. Is this just internet hype and smoke and mirrors with dyno queens trying to push product, or something attainable for the blue-collar weekend racer? We decided to take GMs latest pushrod V8 offering, a 6.6-liter truck engine, and conduct an L8T dyno shootout.

What in the world is an “L8T”?

Since the 2020 model year, GM has offered a 6.6-liter V8 engine as the heavy-duty base gas engine for its heavy-duty pickups under the RPO code “L8T.” It is part of the direct-injected Gen V LT engine family and is the only LT-based production engine that utilizes an iron block. In stock form, the L8T is rated at 401 horsepower at 5,200 pm and 464 pound-feet of torque at 4,000 rpm, perfect for a 3/4-ton or 1-ton truck that needs to tow heavy loads with ease on low-octane pump gas.

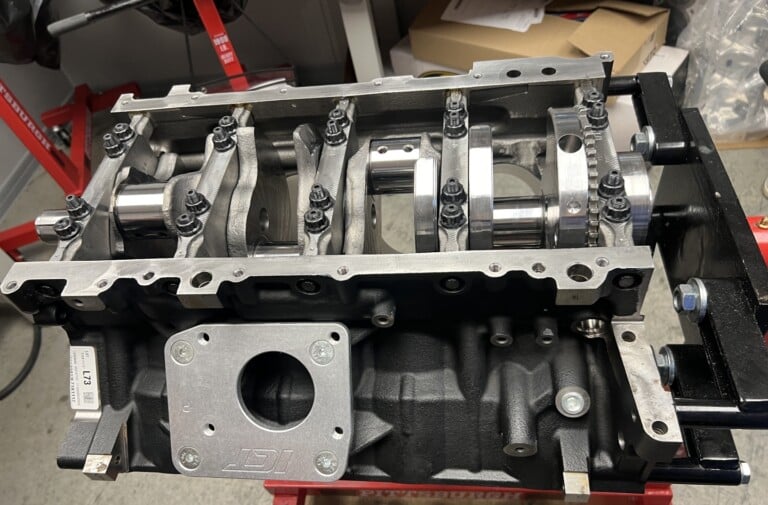

When you order your Chevrolet Performance L8T crate engine, this is how it comes. Complete from intake to oil pan, but no accessory drive, exhaust, or engine wiring.

The L8T shares the same 4.065-inch bore as its 6.2-liter brother, but with a 3.858-inch stroke versus the 6.2’s 3.622-inch stroke to gain the extra 24 cubic-inches. The iron block is cheaper to manufacture than aluminum and is better at handling the additional heat and load a heavy-duty Silverado will see in its lifetime. The block shares the same architecture as the rest of the Gen V small-block family, like a 9.240-inch deck height, 4.400-inch bore spacing, main bearing diameter, and even the bell housing bolt pattern out back.

The 6.6 liter L8T also shares the same cylinder head casting as the 6.2 liter L86 and LT1 engines, but with different materials for the valves, like Inconel exhaust valves, to handle the rigors of heavy loads and high heat for long periods of time. The pistons are also made out of hypereutectic aluminum alloy but with a different design to lower compression to 10.8:1, which when combined with the direct-injection EFI, allows the L8T to be run on low-octane gasoline.

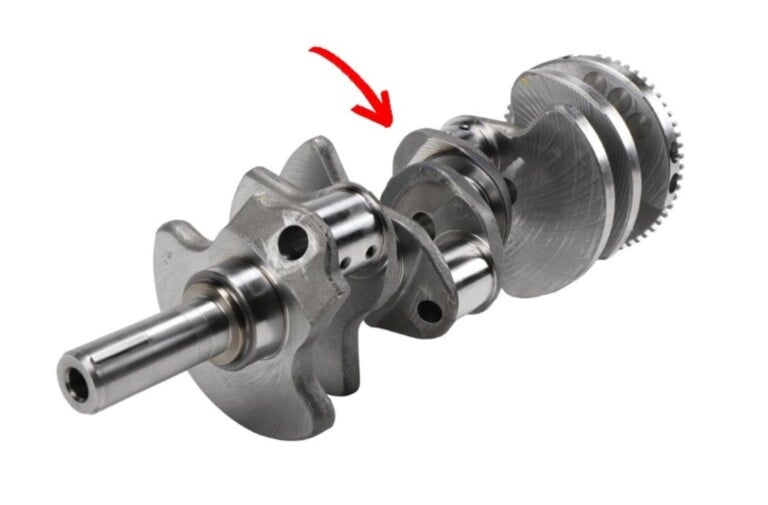

The picture on the left is of a stock LT1 crank, note the lack of…

Click Here to Read the Full Original Article at DragzineDragzine…