We’ve all heard it before, “Your engine is basically an air pump”, and while it certainly is a little more complicated than that, the basic principle remains true. So it goes without saying that one of the most important decisions you can make when picking the next combination of parts for your next engine build is the cylinder heads you will torque down to the short block. From naturally aspirated to high-horsepower power adders, you need a quality head that will meet your needs for flow. The LME LT1/LT1 Racing Heads bring you the highest flowing Gen V LT cylinder head on the market.

Late Model Engines pulls a new 6-bolt bare casting straight from Edelbrock’s foundry right here in the USA. These castings feature a thicker deck surface for superior head gasket retention as well as a thicker casting design overall. This extra material means these heads can withstand higher cylinder pressures compared to the OEM head and have enough meat in the runners to be CNC machined to whatever LME desires without being constrained by a lack of material.

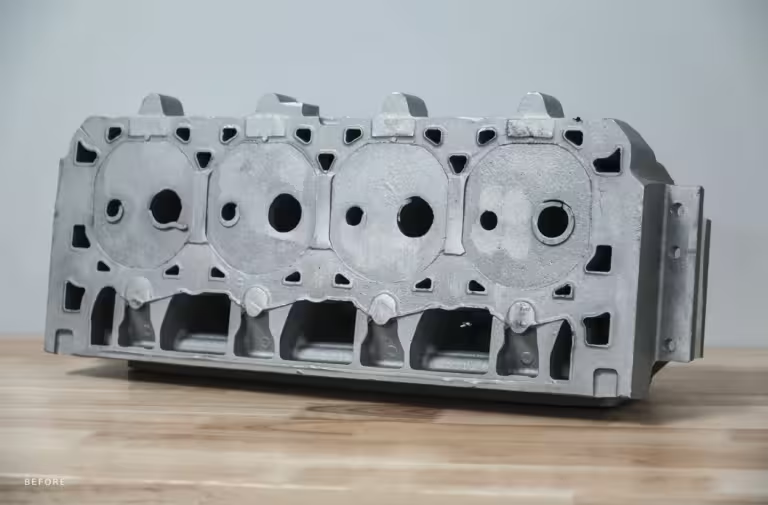

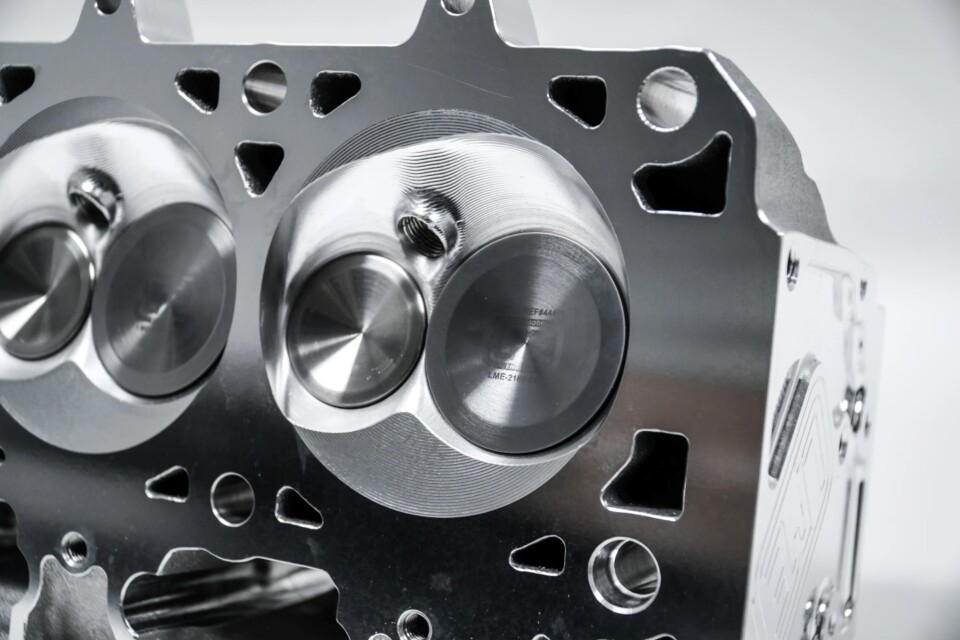

On the left is a picture of the bare unmachined casting as it comes from the foundry in San Jacinto, California. On the right is the finished product, ready to run.

But this isn’t just a Gen V LT cylinder head made thicker to withstand extra abuse with boost, there are also design changes that attribute to extra flow and port velocity. The exhaust flange location on the cylinder head is very close to the OEM location, so exhaust fitment won’t be a worry, but the port shape has been shaped to be a more direct exit from the valve to the header, improving both flow and velocity.

The LME Racing Heads can be ordered bare, or assembled as seen here with titanium intake valves, inconel exhaust valves, and special valve spring packages.

The intake flange has been thickened to raise the runner, the valve and guide locations have been repositioned, and offers both LT1 and LT4 intake manifold bolt patterns. Raising the runner slightly and revising the valve and guide locations compared to the factory head design increases both flow and port velocity, a big benefit in both naturally aspirated and boosted applications.

The valve spring pockets have been raised as well. This is required by the valve guide repositioning and port reshaping. Raising the valve spring pockets also allows extra material at the seat to withstand higher spring pressures and the ability to machine the pocket for larger…

Click Here to Read the Full Original Article at DragzineDragzine…