When you’re building a boosted engine combination there are multiple things you need to take into consideration. The type of fuel and the fuel system you plan on running should be at the top of that list. You don’t want to build a fuel system that can’t service your boosted engine’s needs.

Since you can find E85 at the pump, and it has a higher octane than pump gas, it has become a popular fuel for those who use boost as a power-adder. While this seems like a win-win, there is a caveat to using E85, your fuel system must be E85 compatible. We’re here to make it easier for you to build an E85 fuel system for your vehicle. We sat down with Doug Flynn from Holley and Nic Santarpia from Fuel Injector Clinic to get some tips about how to build an E85 fuel system for a boosted high-performance street car.

Five General E85 Fuel System Tips

We’re going to consider the fuel pump, fittings, filters, and hoses as parts of the general fuel system. These are the parts that move the fuel from the tank to the injectors. When you’re building a fuel system, all of these items need to be E85 compatible. E85 is ethanol-based, so it will corrode any damage anything that isn’t resistant to alcohols.

Tip 1: Selecting The Proper Fuel Pump For The Application

You know that you need a fuel pump that can handle E85, but there’s more to selecting the correct fuel pump. The pump needs to be able to move enough fuel to support how much horsepower the boosted engine package can generate. The engine is going to burn more E85 than gasoline for the same power output; this is why the fuel pump’s volume capabilities are so important.

“Let’s say you’re going to make 750 horsepower at the flywheel. You need to calculate how many liters per hour that is going to require. There are a lot of different ways of getting there, but perhaps the most common method is to take the brake-specific fuel consumption of the engine, and multiply that by the horsepower. With gasoline, I usually use .5 for the brake-specific fuel consumption figure, or .7 for ethanol,” Flynn states.

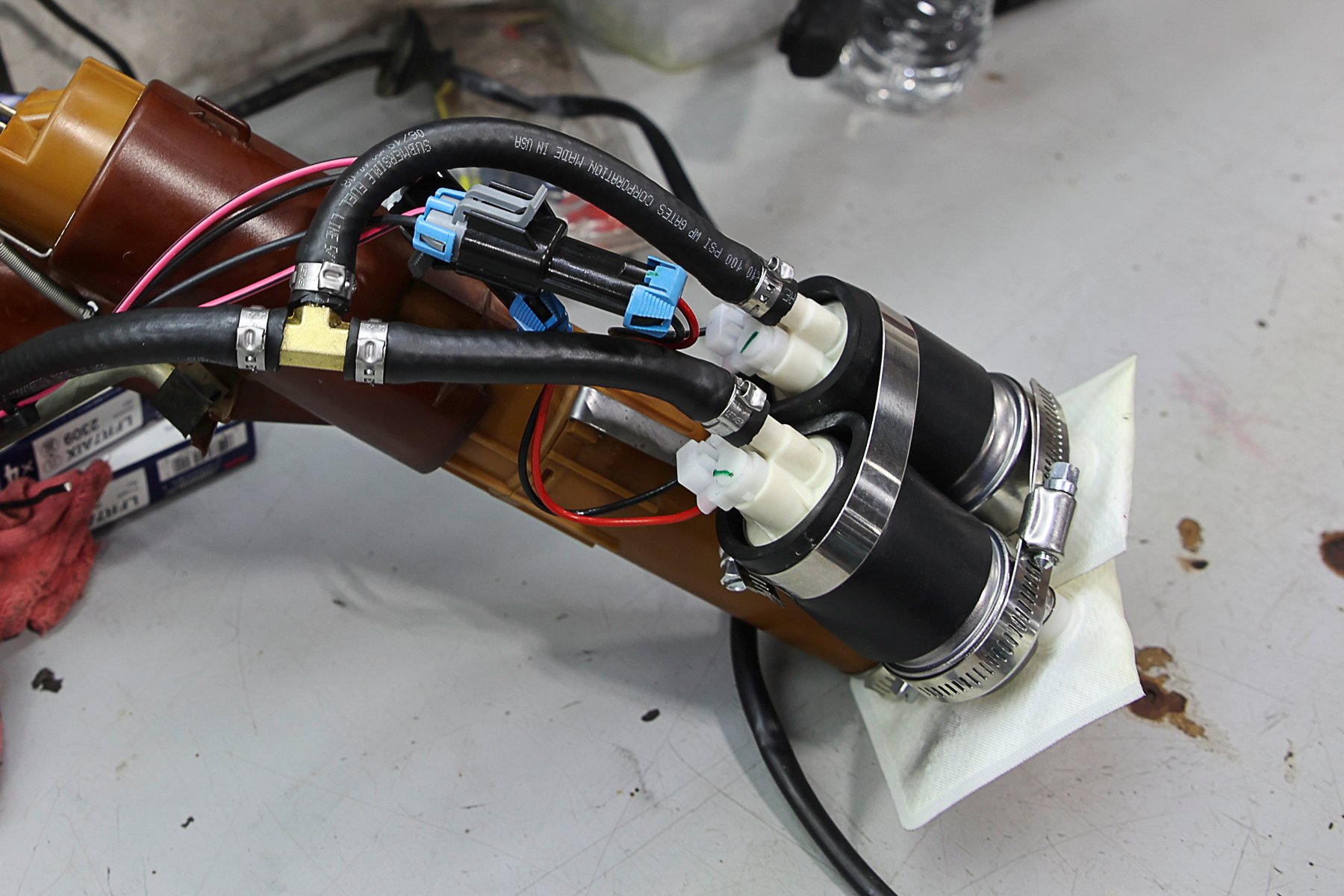

Depending on the application, you might have to double up on E85-friendly fuel pumps to meet the engine’s needs.

So how does that math work out in the real world? “So, in this case, you’d multiply 750 by .7, and that calculates out to 525 pounds per hour of fuel that you would…

Click Here to Read the Full Original Article at DragzineDragzine…