The advantages of a dry sump oil system versus an OEM wet sump lubrication setup are significant. They include improving power through vastly reduced windage, the elimination of oil starvation during hard acceleration, braking, or cornering, allowing for a lower engine placement, and providing a regulated flow of cool, clean oil to reduce engine wear. Another key benefit is the ability to set up system optimized for any given engine and application, and that’s what we’ll delve into here.

For input on the matter, we’ve turned to John Schwarz, President of Aviaid Oil Systems in Chatsworth, California. The company is credited with introducing dry sump technology to commercial motorsports in the late 1960s and has built systems for a wide variety of motorsports applications across the spectrum. Schwarz has headed the company since the late 1990s.

Dry-Sump System Variables

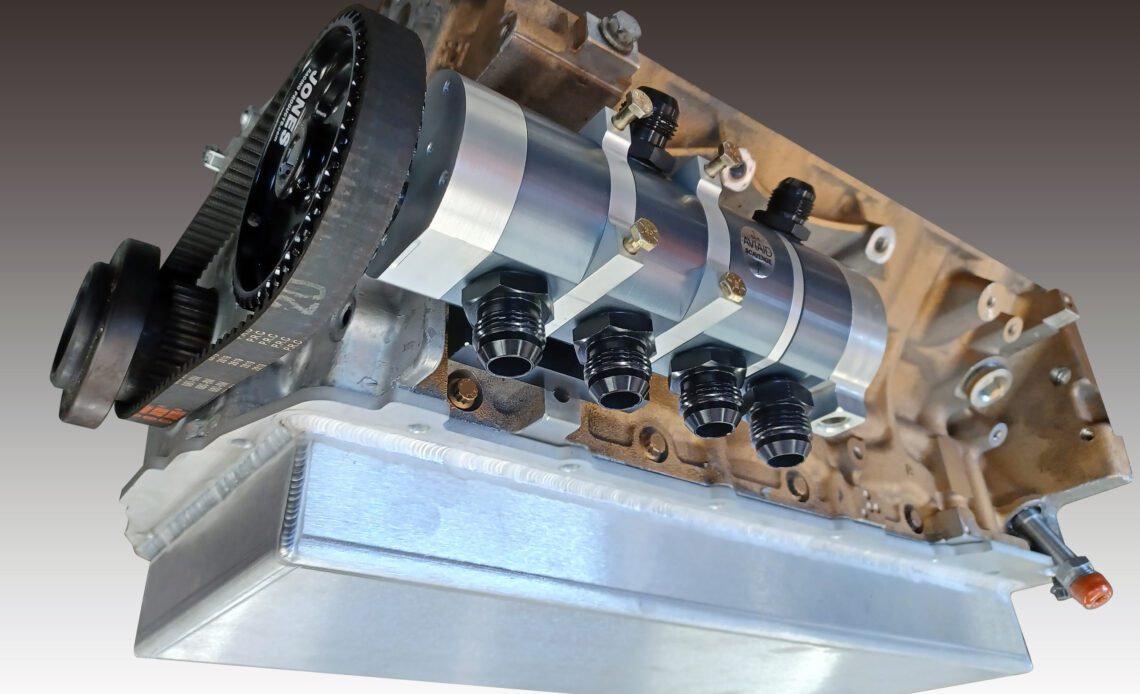

As you might suspect, there are many variables involved in creating the perfect dry-sump system for a given engine combination. The “heart” of the system is the pump itself, which can range from a simple single-stage pump that only handles pan scavenging all the way to complex nine-stage setups with extra sections for power steering and fuel delivery. By far, most systems are three- or four-stage setups with one pressure section and the rest configured to evacuate the pan.

There are a number of variables to consider, the first being the individual pump size. Aviaid offers no less than five different-width sections, ranging from 1 inch-thick to 2 inches-thick in .250-inch increments. Obviously, the larger the section thickness, the higher the throughput. Then there is the type of pump section to consider. In addition to its popular gear-type Series 1 pumps, Aviaid offers a Series 2 design with Roots-type rotors instead of gears in all the scavenge sections. Besides capacity, these different styles have different efficiency ranges that can be tailored to the specific combination.

On the left, you can see the traditional spur-gears of the Aviaid Series-1 pumps. On the right, you can see the more paddle-like lobes of the Roots-style Series-2 pumps. Both designs have different operating ranges, but operate under the “thicker equals more flow” principle.

Pump Mounting and Drives

The pumps themselves are driven through various means, including Gilmer and HTD belts with crankshaft/damper-mounted pulleys, as well as cam drives…

Click Here to Read the Full Original Article at DragzineDragzine…