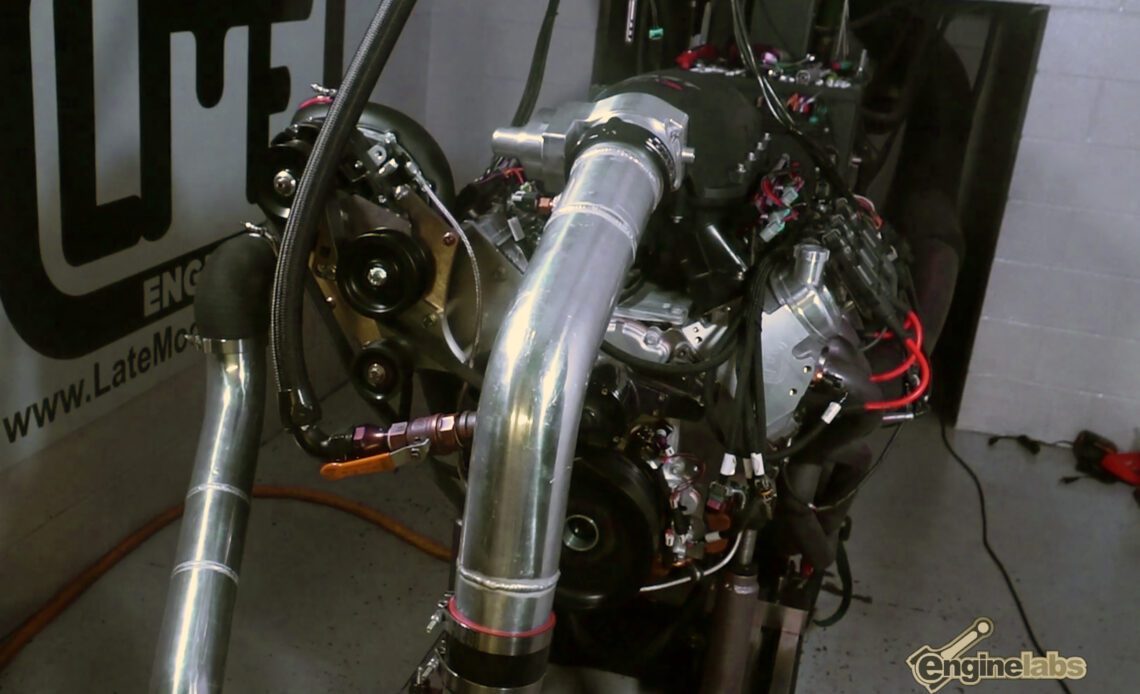

At the 2021 PRI Show, with the help of Late Model Engines, we assembled a 427 cubic-inch, all-aftermarket LS engine on the show floor with the sole intention of giving it away to a lucky winner (hence the name, “giveaway engine”). Once assembled, the engine went back to LME to be dyno-tested with the winner’s choice of Vortech supercharger.

As you might be able to tell from the timing of this article, the winner chose something other than what was on the engine, and the parts situation meant there was a delay in making everything happen. So, since it has been a minute since we covered this build, let’s recap what, exactly, went into this beast of an engine.

The Mighty Short-Block

We not only wanted this engine to make a big number on the dyno, but we wanted it to do it reliably at that power level. The easiest way to ensure longevity is to overbuild the foundation. For that, we turned to Dart and one of its SHP big-bore iron blocks. The SHP block will not only withstand all the power we want to throw at it, but thanks to the priority-main oiling, it should live at that power level for a long time.

LME did all the machine work to prep the block — including CNC deck surfacing, align honing, and finishing the bores at 4.125 inches — prior to the show. At the show, LME’s rockstar engine-builder, Vinnie Monighetti, made short work of the assembly. Starting off with dropping a set of coated Clevite bearings into the mains, Monighetti then grabbed the crank before torquing the ARP main stud kit.

LME machined the Dart SHP iron block to all the final specifications. Besides being strong like ox, the iron Dart block has a host of improved features to help the engine remain reliable at elevated RPM and boost levels. Monighetti went through and checked the clearances one last time before dropping in the crankshaft.

For this project, we chose a 4.00-inch stroke, forged-steel unit from Callies. The Magnum series crankshaft is manufactured from 4340 steel that undergoes several heat treatments. With gun-drilled mains and fully profiled counterweights, the Magnum checks all the boxes, including having a full eight counterweights for extra smoothness at elevated RPM.

The Callies Magnum crankshaft is a fully counterweighted design with fully profiled counterweights in order to help reduce windage. The extra center counterweights provide additional high-RPM stability to the engine.

Attached to…

Click Here to Read the Full Original Article at DragzineDragzine…