In fact, just like with every other area of current grand prix machinery, teams are constantly seeking marginal gain improvements to help make them winners.

Taken down to its most basic element, this means making things lighter, and stronger – and ensuring that every part is totally fit for purpose.

Teams are also always looking for signs of any revolutionary technology that can help shoot them clear of their rivals.

Progress in the raw materials that cars are made from is not something that comes purely from within the factory walls of F1’s competitors, though, because they are reliant on outside suppliers that have a much better understanding of the composite industry.

And none stands out more on the current F1 grid than Belgian multinational science company Solvay. It helps supply every F1 team on the grid, to a greater or lesser extent, with its carbonfibre products, which go on to be ultimately shaped and turned into the car parts we see out on track.

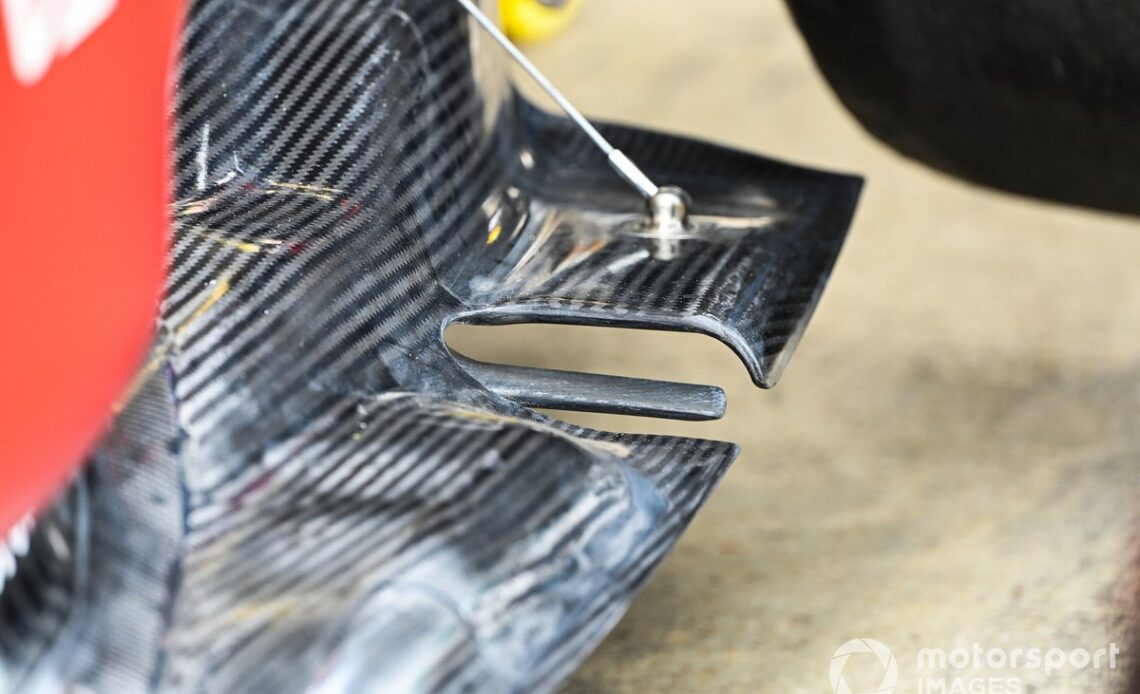

Ferrari F1-75 floor detail

Photo by: Mark Sutton / Motorsport Images

Solvay has seen dramatic changes in the technology and understanding of carbonfibre since it first appeared in F1 – as teams have constantly pushed things to the limit.

As Gerald Perrin, Global Program Director of Automotive at Solvay, tells Autosport: “In the past 20 years, every single car winning the F1 championship was manufactured with Solvay materials.

“We have been extremely pivotal in working with the teams in improving the safety of the cars. But the type of materials that are used today are completely different to what was designed in the ’80s.

“There is optimisation of the fibre and the resin, and how you combine and interact those two materials.

“Everything has been completely optimised, while in the ’80s it was probably one fit for all: it was lighter than metal so it was already super nice!”

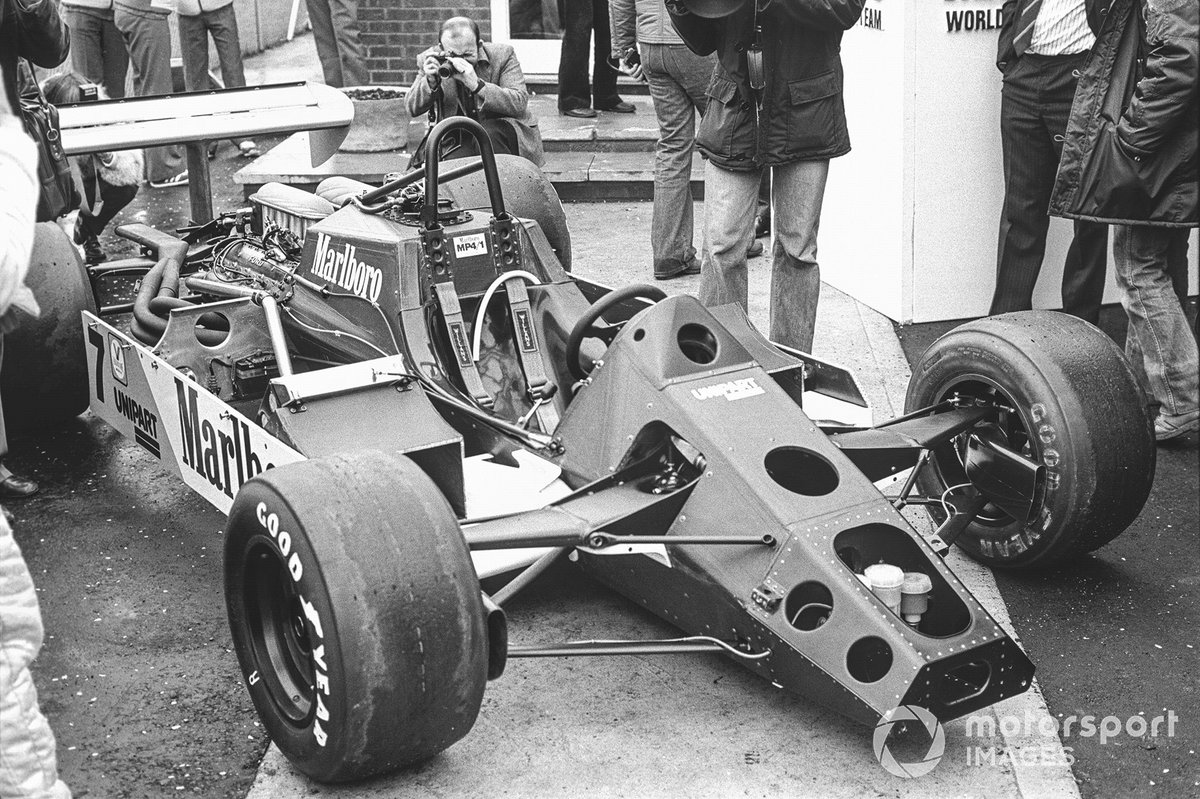

McLaren MP4/1

Photo by: Motorsport Images

While decades ago, a car may have used two or three different types of carbonfibre for varying purposes, now it’s a completely different ballgame with around 40 types throughout.

Mark Steele, customer engineering manager of automotive composites for Solvay, says: “When I think back to the 1980s they used one or two, maybe even three, different types of epoxy resins to translate the performance into the fibre.

“Nowadays, the cars don’t use one or two resins, they use multiple resins. They are very, very bespoke resins for very specific applications:…

Click Here to Read the Full Original Article at Autosport.com – Formula 1 – Stories…