Ever wonder how a cast-aluminum product is produced? Or how does Edelbrock’s “Made in U.S.A.” sticker stack up regarding its authenticity? Thanks to the guys over at the Stapleton42 YouTube channel, we’ve been given a candid glimpse inside the company’s aluminum-production process.

From aluminum ingots and ear-splitting casting facilities running on cutting-edge software to the machining stages and “Plasma Black” finishing, every step of the Edelbrock intake manifold creation process is completed right here in the United States. And these are but a few of the many aluminum products being churned out by this all-American aftermarket manufacturing firm.

But there’s way more to this iconic automotive aftermarket brand than some fancy futuristic data-logging programs and an infatuation with doing everything from start to finish in-house. If you are going to set the bar in the aluminum casting business, you’ll need to have a few tricks up your sleeve. Which, in Edelbrock’s case, translates to a slew of surprises.

Made with “MAGMA”

We start things off at the San Jacinto, California, side of Edelbrock’s operations, where much more than molten metal is used. Since we live in the “modern age” of aftermarket automotive parts manufacturing, everything starts with software.

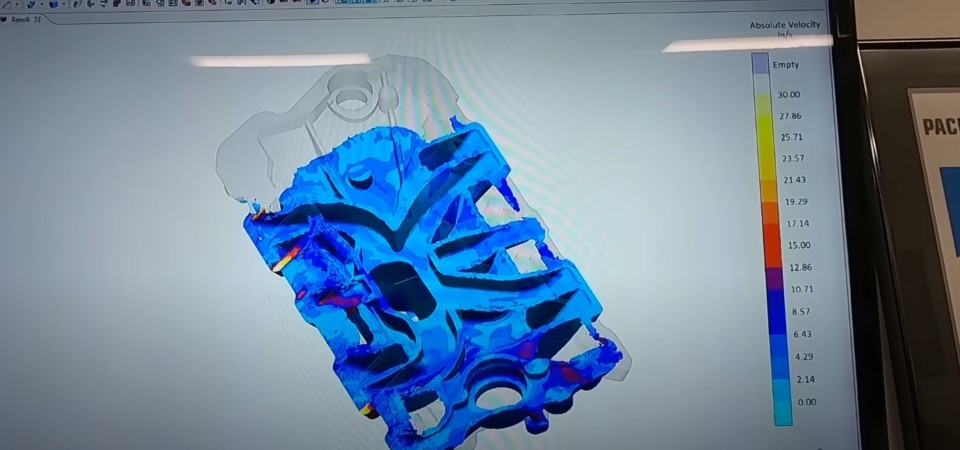

For the better part of the past 8-years or so, Edelbrock has relied upon a German casting simulation program called MAGMA, or Magmasoft. Edelbrock’s utilization of this technology has allowed its engineers to produce what many consider to be some of the highest-quality aluminum castings on the planet.

With this Magmasoft program monitoring every stage of the casting process, quality control experts can keep an eye on everything of importance. Thickness levels, temperature fluctuations, fill velocity, and myriad other unknowns that only computer software can illuminate are clearly exposed onscreen.

Before using this data-logging programming, Edelbrock’s engineers had to make a casting, cut it up, and machine various areas to expose imperfections. The introduction of Magmasoft to the brand’s daily operations has produced a multitude of production perks.

Furthermore, this program serves as a watchdog for any imperfections or issues that may arise during the casting process. This exposure of hidden…

Click Here to Read the Full Original Article at DragzineDragzine…