Electronic fuel injection (EFI) has gone from being rare to being widely used as a form of induction for high-performance vehicles. While you see more EFI on vehicles, there’s still plenty rocking a carburetor of some kind. In this video, Jeremy Stoermer takes us on a journey to Bowling Green, Kentucky to see how Holley carburetors are built.

Holley has been making carburetors for all kinds of applications since 1903 — from a basic two-barrel carburetor, all the way to a massive 1,475 cfm Dominator, chances are Holley makes a carburetor that will bolt to whatever you’re running. Holley has perfected the process of mixing air and fuel so it can be sent into your engine.

Just like any assembly process you have to start with raw parts, and that’s exactly what Holley does. Each carburetor’s main body, throttle body, metering block, and fuel bowl all go through a series of CNC machining processes to get them ready for assembly. After each part is machined, it gets an ultrasonic bath and a quick blow-dry before it’s moved to the next step.

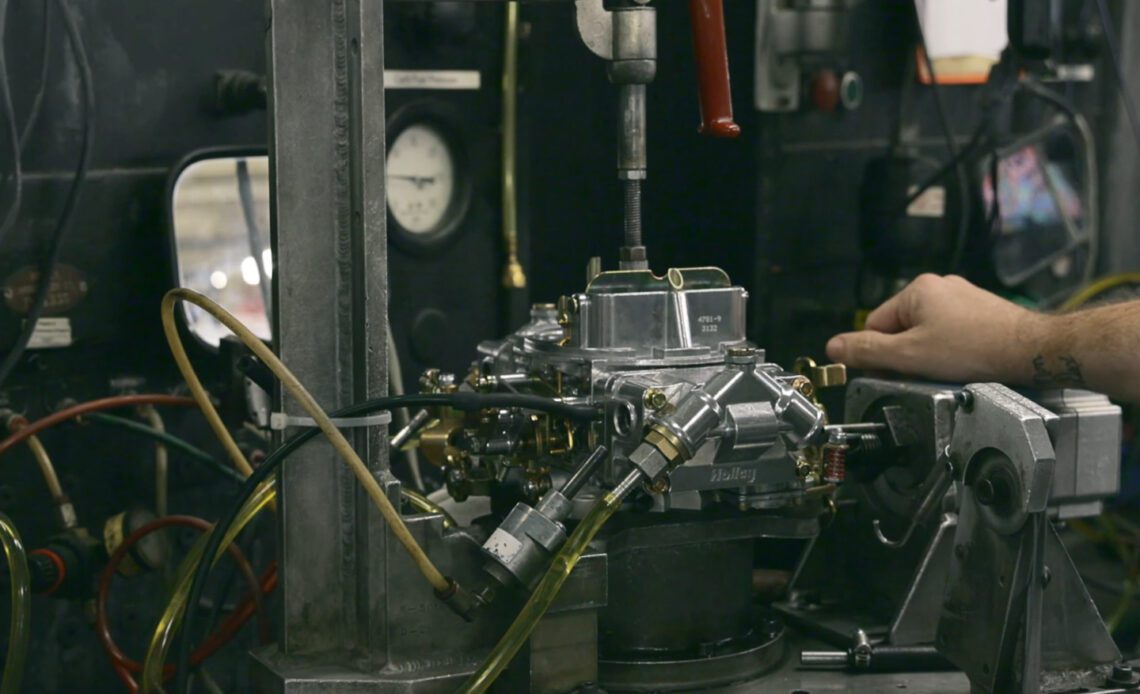

Holley’s assembly process requires each part of the carburetor to be individually assembled. The fuel bowls, metering blocks, and throttle bodies go through individual stations to be completed before they’re moved to the main line for final assembly. The final step after the carburetor is assembled is a trip to the flow bench. Each carburetor is wet-flowed with mineral spirits to ensure they’re flowing the proper amount of air and fuel based on the master carb calibration.

You’ll want to watch this entire video to get all the fantastic details on how Holley carburetors are made.

Click Here to Read the Full Original Article at DragzineDragzine…