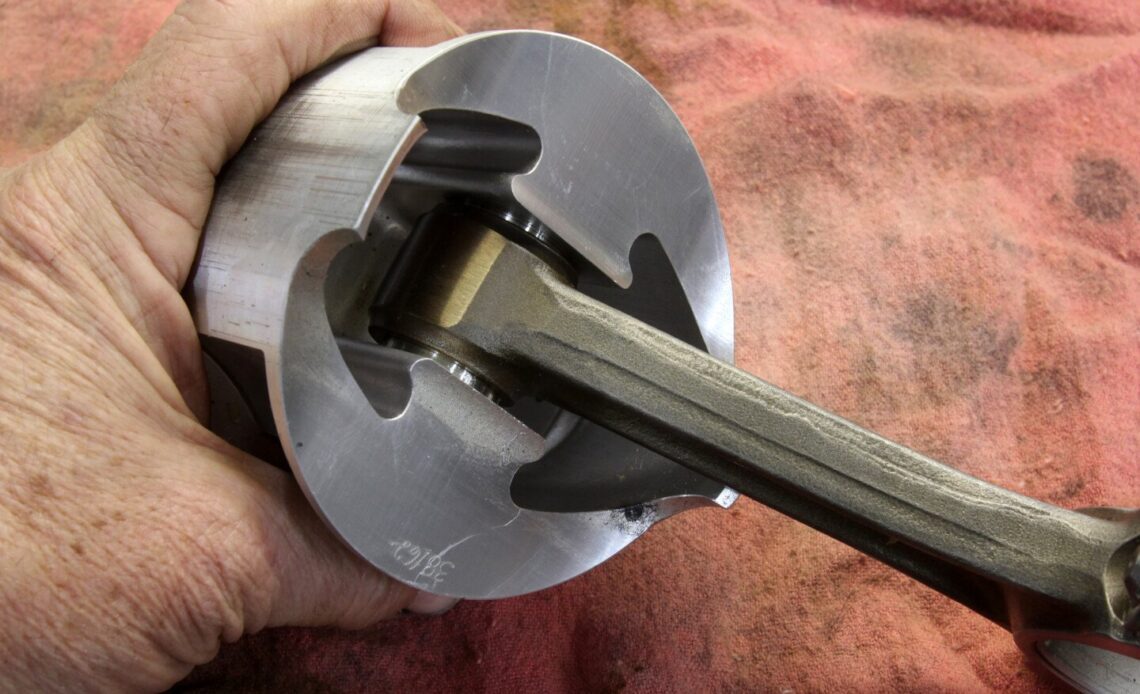

Throughout an engine, clearances are critical. We often talk about things like rod bearing and main bearing clearances, but one extremely critical clearance we don’t talk about much is the wrist pin clearance. We just take for granted that if the wrist pin goes into the rod all is well. When you’re building a floating wrist-pin combination, the clearance between the pin and the small end of the rod is something that should be checked and set in a build.

In the last several new connecting rod sets we’ve purchased for floating rods, nearly all would allow new wrist pins to easily slide in place, but the clearance was less than 0.001 inch — often as tight as 0.006 to 0.007 inch. These wrist pins really need 0.001 to 0.0012 inch of clearance to ensure proper lubrication. Always have your machine shop check this, especially on new connecting rods, and open the clearance if they measure less than 0.001 inch.

An engine builder friend recently experienced piston damage on a 750-horsepower, carefully-built small-block Chevy where the problem was initiated by tight wrist-pin-to-connecting-rod bushing clearance. The binding between the two components created a thrust load on the piston. This in turn caused the piston to scuff the cylinder wall, which eventually led to oil control problems. The whole chain of events was traced back to a too-tight wrist pin bushing clearance.

Full-floating rods need proper clearance between the pin and the connecting rod to allow for both proper lubrication and also to prevent binding the wrist pin. Often a tolerance stack-up can occur where the pin clearance is too tight, so it’s best to check this whenever using a new combination of connecting rods or pistons.

Click Here to Read the Full Original Article at DragzineDragzine…