When it comes to building an engine, better tools often lead to a much better assembly process. Whether it’s through increased ease of use, faster task completion, or more accurate results, having nice tools makes the process of building an engine nicer for the person turning the wrenches (as a reader of EngineLabs, that person is most likely you). Enter Summit Racing’s Pro Ring Filer, which does all three of the things mentioned above.

Properly sizing the piston ring gap is an absolutely crucial step in any engine build. That spec is important, and properly achieving that gap is a lot more challenging than it first appears. First and foremost, you must remove the proper amount of material in order to achieve the proper end gap. Next, you need to ensure that the end you’ve been filing on is square in two separate axes. Third, you need to ensure your finish is smooth, clean, and free of any burrs that might cause physical damage or hot spots once installed.

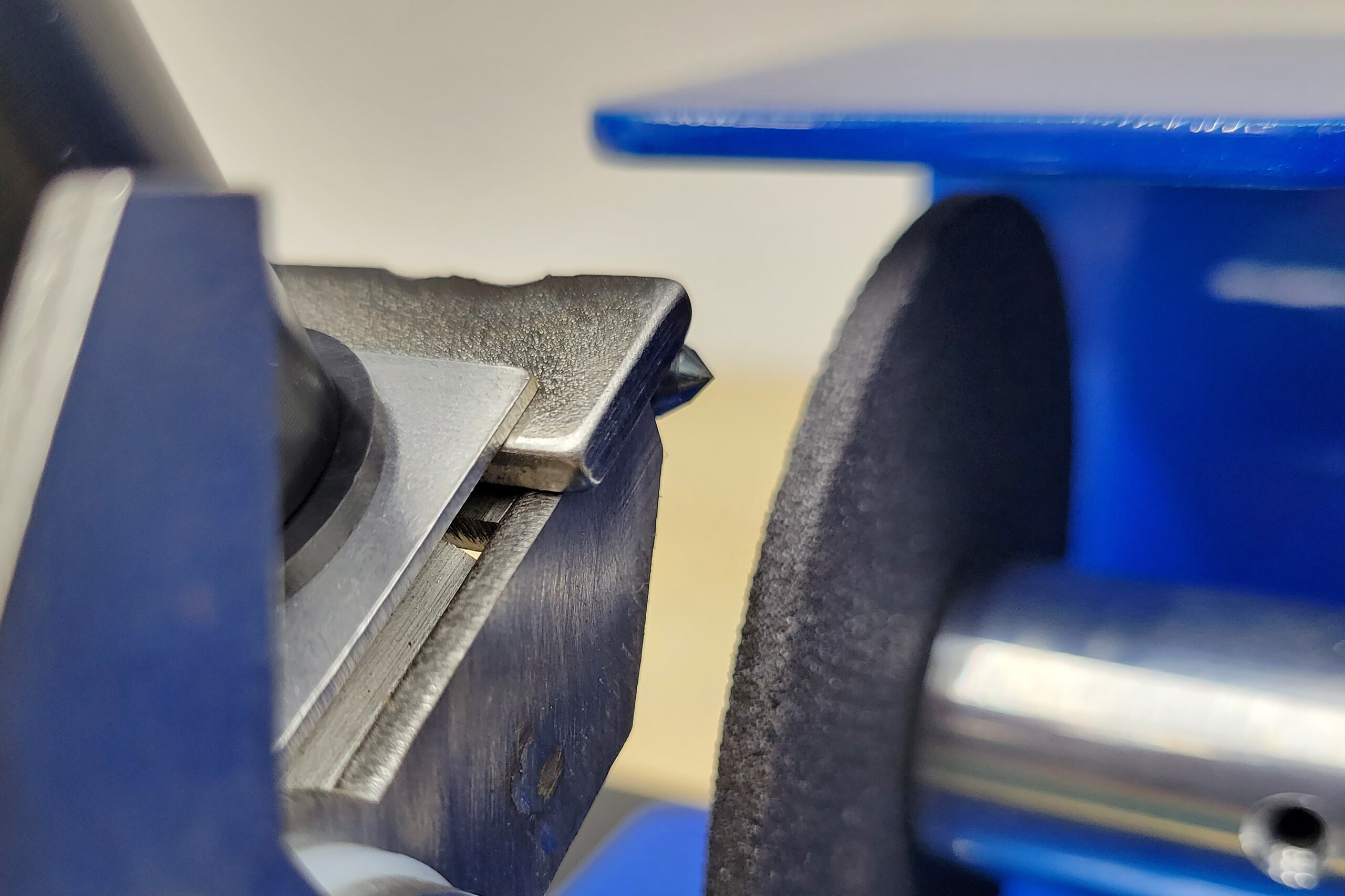

The included diamond wheel dressing tool is designed to dress your abrasive wheel, making it square to the ring end. It fits in the grinder the same as a piston ring being run against the wheel.

There are a number of types of filers on the market. The manual styles can be as simple as a hand file, but are usually a hand-cranked grinding wheel. The Summit Racing Pro Ring Filer is a power filer — that is, it uses an electric motor to spin the grinding disc. Even within this category, there is a wide range of styles, ranging from a manual-style wheel with a drill motor attached to it, up through various levels until you get to the tool you see here, which has every bell and whistle possible. Oh, and it’s available in a huge array of colors and candy finishes.

Building A Better Mousetrap

Designed and built right here in the USA, with American materials, we’ve actually seen them being built in-person while down in Phoenix, Arizona. The heavy-duty steel parts are precision bent, minimizing the number of welds needed in the units’ construction. It uses either a 110-volt or 220-volt high-precision electric motor (depending on your electrical requirements) that sounds only like a smooth hum at full song.

Here you can see the progress of dressing the wheel over about .012 inch of feeding. While that is only .012 inch over an inch and a half (or half a degree), now we’re sure to be 100-percent square.

At first, the Summit Pro Ring Filer might look complicated and intimidating, with several…

Click Here to Read the Full Original Article at DragzineDragzine…