Over the course of three days, December 7-9, 2023, The annual PRI Show in Indianapolis, Indiana played host to some of the latest and greatest the Performance Racing Industry had to offer. It also was the site where our 1,200-horsepower Gen-III HEMI giveaway engine came to life. Starting Thursday, Late Model Engines’ Vinnie Monighetti expertly assembled the Mopar live on the show floor, right in the Power Automedia booth.

As in previous years, we are teaming up with Summit Racing to build this giveaway engine to award to a lucky winner, entered at EngineLabsGiveaway.com (So make sure to get entered now. Here’s an additional entry — WEDGE — pay attention, because there’s another code for another additional giveaway engine entry later in this article.) However, unlike previous years, this engine is A) a Gen-III HEMI and B) uses a positive-displacement supercharger to reach its 1,200-horsepower goal.

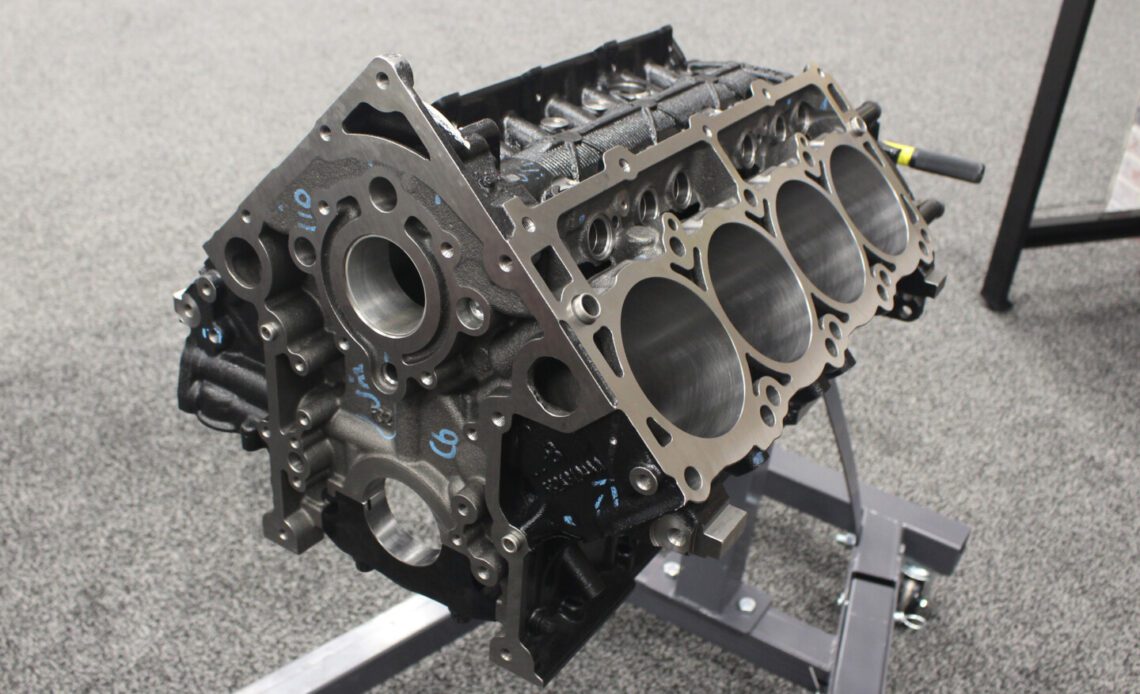

Before the show, the team at LME machined the block, made sure the big end of the connecting rods were round and on-size, packed up the parts, and put them on the truck for Indy. From there, we loaded them into our booth the day before the show, and when the show opened on Thursday, Vinnie got to work turning the pile of boxes into an impressive powerplant.

The base for this build is a BGE iron truck block, that has been opened up to 4.095 inches and clearanced for a 4.050-inch stroke.

Building The Base

If we’ve said it once, we’ve said it a thousand times; the most important part of an engine build is the block. It is the foundation of every other part, and if it isn’t right, or up to the task, the engine will only be worth its weight in scrap iron. For this project, we started with a factory-new BGE 6.4-liter iron truck block, provided by Callies Performance Products. The BGE (short for Big Gas Engine) block is the most desirable of the OEM HEMI blocks, thanks to its high-nickel iron alloy and revised coolant passage design with additional material thicknesses at key points, internally. This creates better bore stability in high-horsepower applications. LME opened the factory 4.090-inch bore up to 4.095 inches.

LME then fitted a set of Energy Manufacturing’s billet steel main caps along with an ARP Main Stud Kit to the block, replacing the factory cast steel pieces. Then, a quick align-hone made sure the main journals of the new caps were all perfectly sized and aligned. While…

Click Here to Read the Full Original Article at DragzineDragzine…