With increasing drag racing performance comes the need to get all that related race car inertia stopped at the other end of the track. As a material, stainless steel is not new for competition disc brakes rotors, but the engineering team at Strange Engineering has taken the stainless brake package to a new level.

The recent expansion of the Strange stainless steel brake kits offers greater benefits compared to traditional steel brakes. We spoke to J.C. Cascio, Director of Business Development at Strange, to learn more about its latest engineering efforts.

New Developments Never Stop

Cascio offers some insight into the stainless steel material trend. “Strange Engineering is in a constant state of innovating and refining that improves our product lines. The Strange Engineering line of brakes is no exception.”

The stainless disc rotor designs provide a safer and more efficient rotor material that demonstrates 48 percent greater yield strength at 1,000 degrees Fahrenheit during hard braking as compared to steel. These material benefits also further maintain rotor integrity.

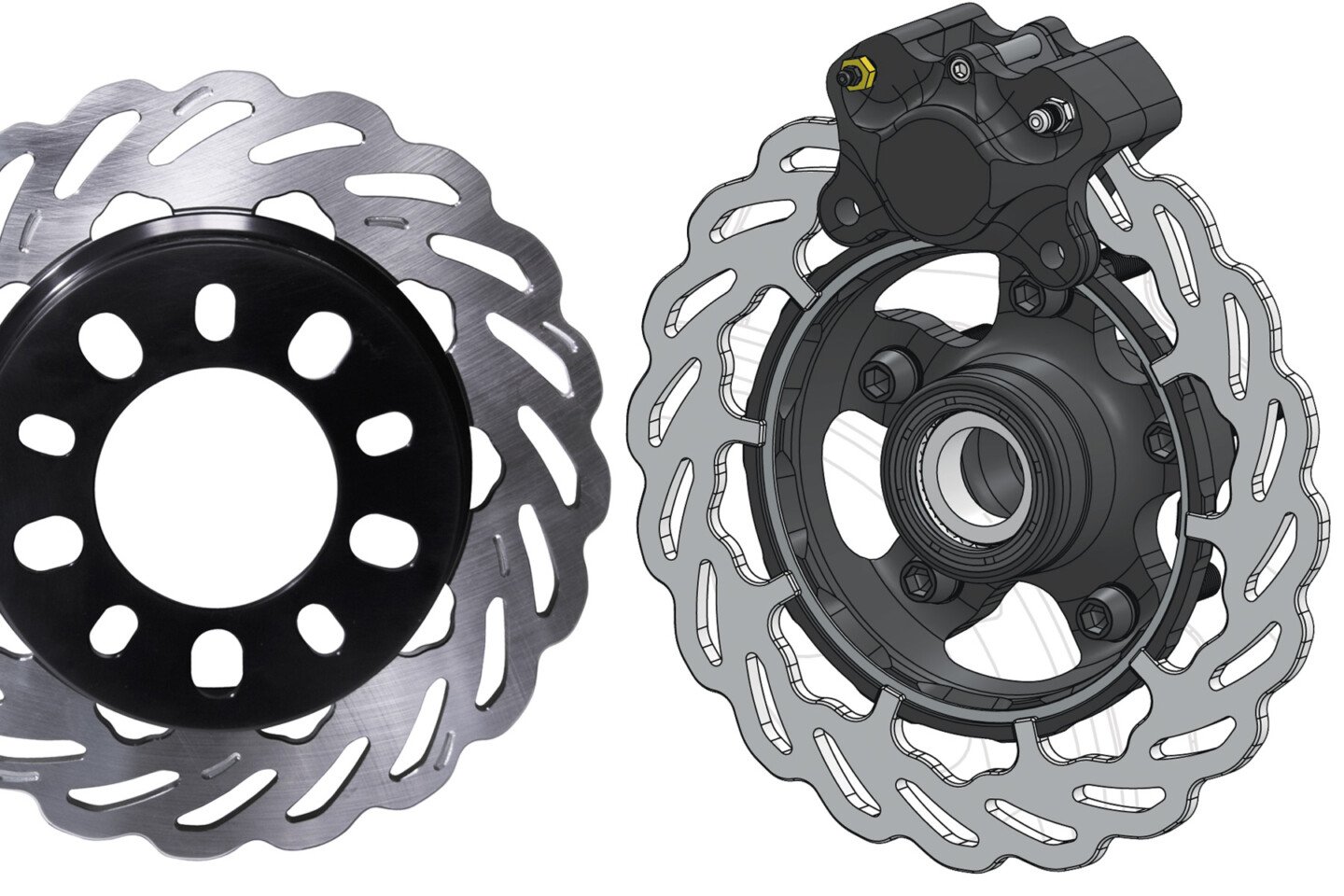

Strange Engineering continually updates its extensive product lines, such as its proven steel brakes (left). Strange has expanded its stainless steel brakes with its Pro II Stainless Steel Brake Kits (center) and the unique Strange Evolution brakes. The stainless brake lines use a new Dynamic Drive Mount between the billet steel brake hat and the stainless rotors.

Two versions of Strange stainless steel rotor designs are available; the traditional Pro II S Series stainless rotor uses a similar design to the Strange steel rotors with directional slots. The new Evolution S stainless rotor features a unique aero-slot pattern design with much less rotating weight compared to the Strange steel brake rotors. Both of the stainless brake designs are developed for racers desiring minimal weight while not compromising brake performance.

The Pro II S and Evolution Stainless Steel Dynamic brakes utilize Strange’s innovative Dynamic Drive Mount (DDM) system. The rotors are connected to the new billet aluminum DDM hat with internal Spirlox fasteners that eliminate bolts between the hats and rotors. This new feature reduces common warping, coning, and cracking.

The scalloped design of the aero-slot rotor further reduces rotating weight and promotes even heat dissipation compared to some common round drilled holes. These rotors typically measure 11.250 inches outside diameter, with a thickness…

Click Here to Read the Full Original Article at DragzineDragzine…