The seal between a cylinder head and an engine block is extremely important. If you don’t make sure that seal is leak-proof, there’s a good chance the engine is going to have problems. We talked with Scott Hesselgrave from Air Flow Research (AFR) and got some tips about how to make sure your cylinder heads and engine block can get the best seal possible.

There’s really not much keeping the combustion process contained inside a cylinder besides a gasket. The gasket is the meat in the block and cylinder sandwich, but it’s not the main reason the seal between the two parts remains intact There’s plenty of prep work that goes into making sure the surface of the block is ready, that the cylinder head is as flat as possible, and that the fasteners have been used correctly.

You want the surface of your block to be so clean surgery could be performed on it. This will make it much easier for the cylinder head to seal up to the block.

Initial Prep Work For A Good Seal Between The Heads And Block

We’re going to mention this a few times in this article, but prep work is the backbone of a good seal between a cylinder head and the engine block. The initial prep work you do before you even think about final assembly will set the table for success.

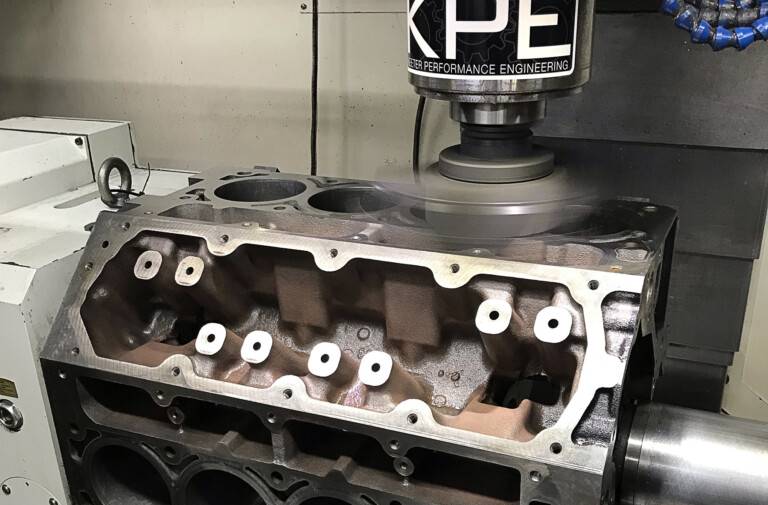

The first step in the prep work process is making sure that the block and cylinder heads have been properly machined and have the right surface finish. You need the deck of the block and the cylinder heads to be as smooth as possible. The machine shop will also need to make sure the block has been cleaned. Any anti-corrosion coatings, gunk, and other containments on the mating surfaces need to be removed. All of the threaded holes should be chased to clear out all debris.

If possible, have the mating surfaces of your heads and block machined. This will ensure they are not only clean, but as flat as possible.

“You want the gasket mating surfaces to have a 50Ra or finer finish. And of course, the head surface needs to be flat. The deck of the block also needs to be flat, not ‘close enough’. People get into trouble when they try to assemble engines with a set of heads or a block that haven’t been checked or machined for flatness,” Hesselgrave explains.

Hesselgrave also recommends that you check everything over one last time, before the first bolt is installed. Make sure the surface of the block doesn’t have any dirt or other debris on it that might have landed there when the rotating assembly was…

Click Here to Read the Full Original Article at DragzineDragzine…