If you’re reading this before April 2, 2024, you can still get entered to win this 1,200-horsepower Gen-III HEMI engine built by Late Model Engines and Summit Racing. If you’re already entered, and have maximized all possible entries, you might want to go back to www.enginelabsgiveaway.com for a few more entries. We’ve been hiding extra entry codes in the giveaway engine articles over the past few months, so if you’ve already found all five, awesome. If not, here they are:

- ELEPHANT

- WEDGE

- HEMISPHERICAL

- TWINSCREW

- FIREDOME

Each one of those codes on the giveaway website will get you an extra entry into the giveaway. With that said, let’s move on to looking at the engine itself.

One of the really neat features of this engine is that it was entirely assembled live on the floor of the 2023 PRI Show floor.

The 1,200-Horsepower Gen-III HEMI

If you are in a heavy reading mood, here are all the links to the previous articles we’ve written on the Giveaway HEMI engine. If you’re not in a reading move, we’ll summarize the build here.

Starting with a cast-iron BGE block, LME machined the surfaces and opened the bores up to 4.095 inches. They then fitted a set of Energy Manufacturing’s billet main caps and ARP main studs. The factory oil squirters were blocked off, and King Engine Bearings were fitted.

?si=C0FB1Q_WQFnRNdDb

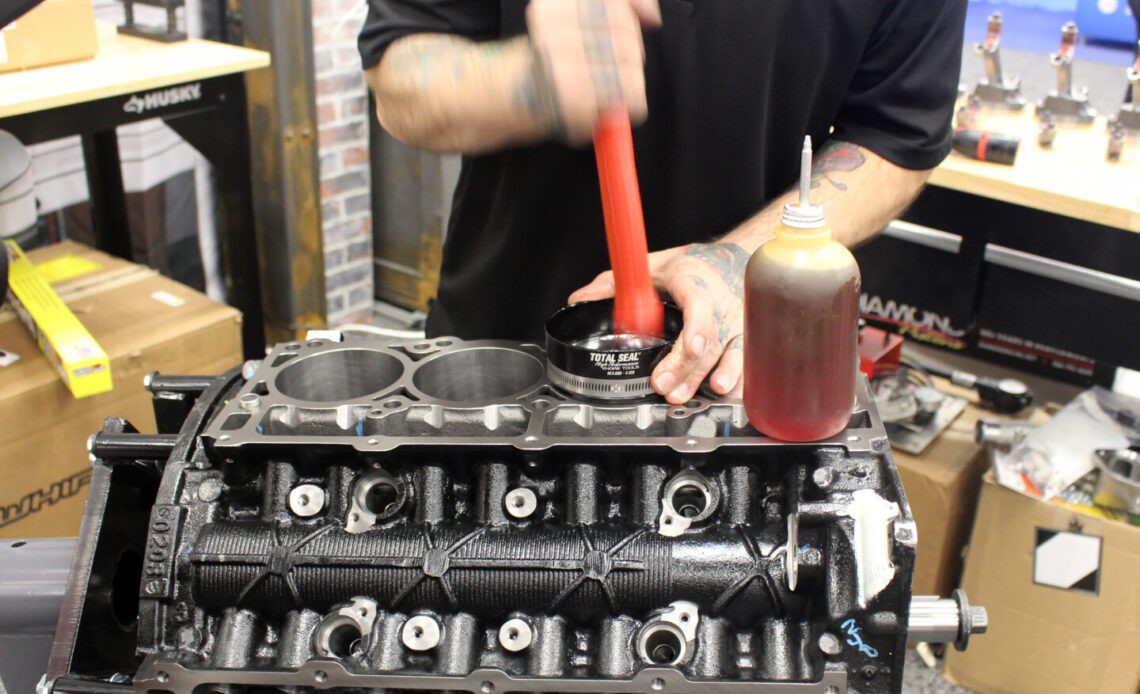

A Callies Compstar forged 4340-steel 4.050-inch-stroke crankshaft was dropped in, accompanied by Callies Ultra Enforcer 6.125-inch rods made from forged 4330V steel. Hanging off those rods are a set of Diamond Pistons’ Hemi2K 2618 forged pistons held in place by some beefy Trend thick-wall wrist pins and Total Seal piston rings. An ATI Super Damper eliminates torsional vibration, while under the engine, a Milodon windage tray designed for the Drag Pack cars was fitted along with the Drag Pack oil pan and pickup tube, coupled with Melling’s Hellcat oil pump.

Moving to the top end, a set of Thitek GenIIIH “Bear” cylinder heads were fitted with ARP head studs and sealed with a pair of Cometic MLX head gaskets. A Cam Motion VVT Camshaft was installed along with the factory timing set, but with the VVT locked out. Johnson short-travel hydraulic lifters were then dropped into the lifter bores with 3/8-inch, .080-wall Cam Motion pushrods sitting on top of them. Then a set of Jesel shaft bolt-on rockers were fitted with a set of Stanke Motorsports shaft braces and…

Click Here to Read the Full Original Article at DragzineDragzine…