Although we all like to include upgrades to our trucks, selecting the right option can sometimes be a little daunting. Take for instance a turbo upgrade. There are a plethora of options available, including bigger, compound, and even Variable Geometry Turbos (VGT) or non-VGT swap kits. That last option seems to create a lot of questions, as many enthusiasts are contemplating whether to swap out their VGT for a non-VGT. While doing so might offer a few benefits for some truck owners, doing such a swap does have some implications that you should be aware of — legality being the biggest. So, I thought we should get a discussion going about how to make an informed decision. I want to make sure you guys get good information so I reached out to people that specialize in turbos — KC Turbos.

“The VGT vs. non-VGT argument has been something we have been contending with for a long time,” said Cameron Lewis of KC Turbos. “In our experience, a properly functioning VGT is going to spool faster and make more power through the powerband when compared to a non-VGT in just about any setup under 650 horsepower on a 6.0 and 6.7-liter Power Stroke. The ‘larger’ you go, the bigger the advantage you will see from a non-VGT. ‘Smaller’ setups are much better off with a VGT. However, a lot of this decision comes down to personal preference — for the sound, feel, driving style, etc. It is hard for me to believe people when they say that a non-VGT will spool faster than a VGT. We simply have never seen that through all of our years of testing.”

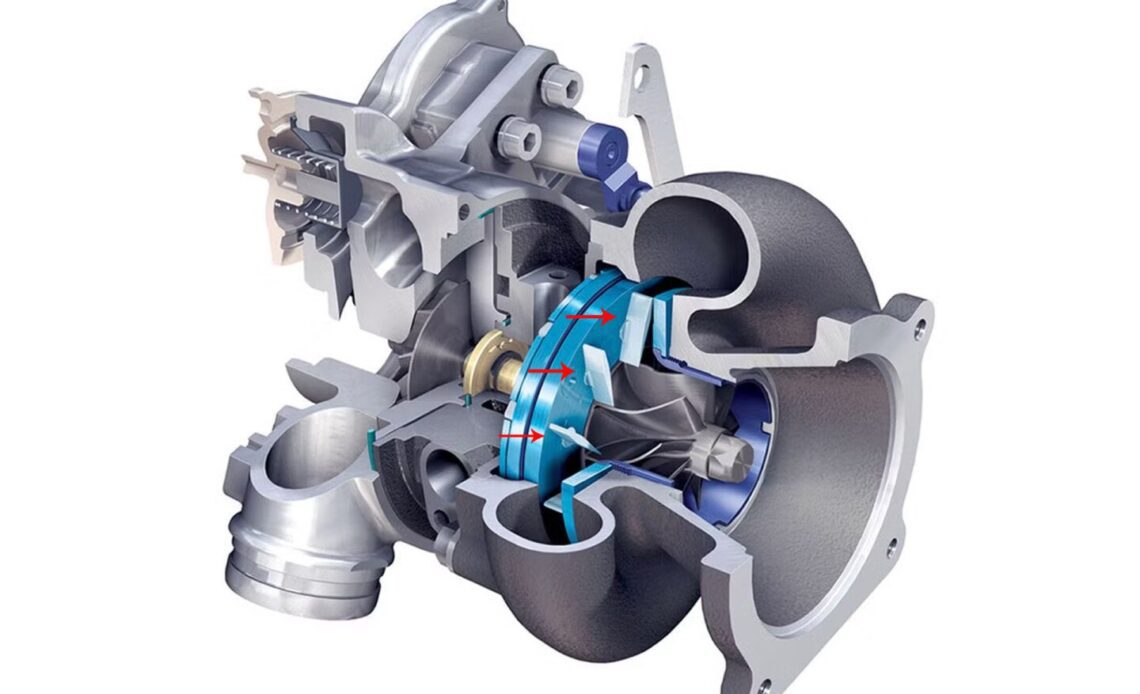

The arrows highlight the variable vanes in this cutaway drawing. These move via an actuator that is attached to the turbo housing.

VGT Or Non-VGT — Let’s Talk VGT

For the last decade, diesel trucks coming out of the factory have benefited from Variable Geometry Turbochargers. Before that, older turbo-equipped trucks utilized a fixed vane turbo. The difference? Let me explain.

A variable geometry turbo means the turbocharger can adjust the path of the exhaust gasses to change their effect on the turbine wheel. The most common method is to direct the exhaust gases onto different regions of the turbine by angling the “variable” teardrop-shaped “vanes” placed around the turbine impeller. These vanes are moved simultaneously by a rotating component called a unison ring.

These teardrop-shaped vanes control exhaust flow through the turbine wheel as they open and close to match the engine’s exact boost…

Click Here to Read the Full Original Article at DragzineDragzine…