There are few things in a dyno room, or under the hood, more annoying than a leaky AN fitting. When they work properly, AN fittings (and flare fittings in general) are ingenious, fluid-tight couplings that require a minimal amount of torque and no external gaskets to seal. The downside to them, is that the mating surfaces require a decent finish on both sides of the equation, making them more susceptible to leaking when damaged. Enter Koul Tools Fitting Fixer.

The Koul Tools Fitting Fixer is available in sizes from -3 AN (3/16-inch) all the way up to -16 AN (1-inch).

When you have a leaking, damaged fitting, no amount of hulking out will make a poor connection seal. Quite the opposite, actually, as overtightening an aluminum AN fitting can further damage, or even destroy the fitting. The only solution is to re-machine the mating surfaces. For female fittings, Koul Tools makes the P-51 Sureseat lapping tool that we’ve highlighted previously. For male fittings, a different tool is required.

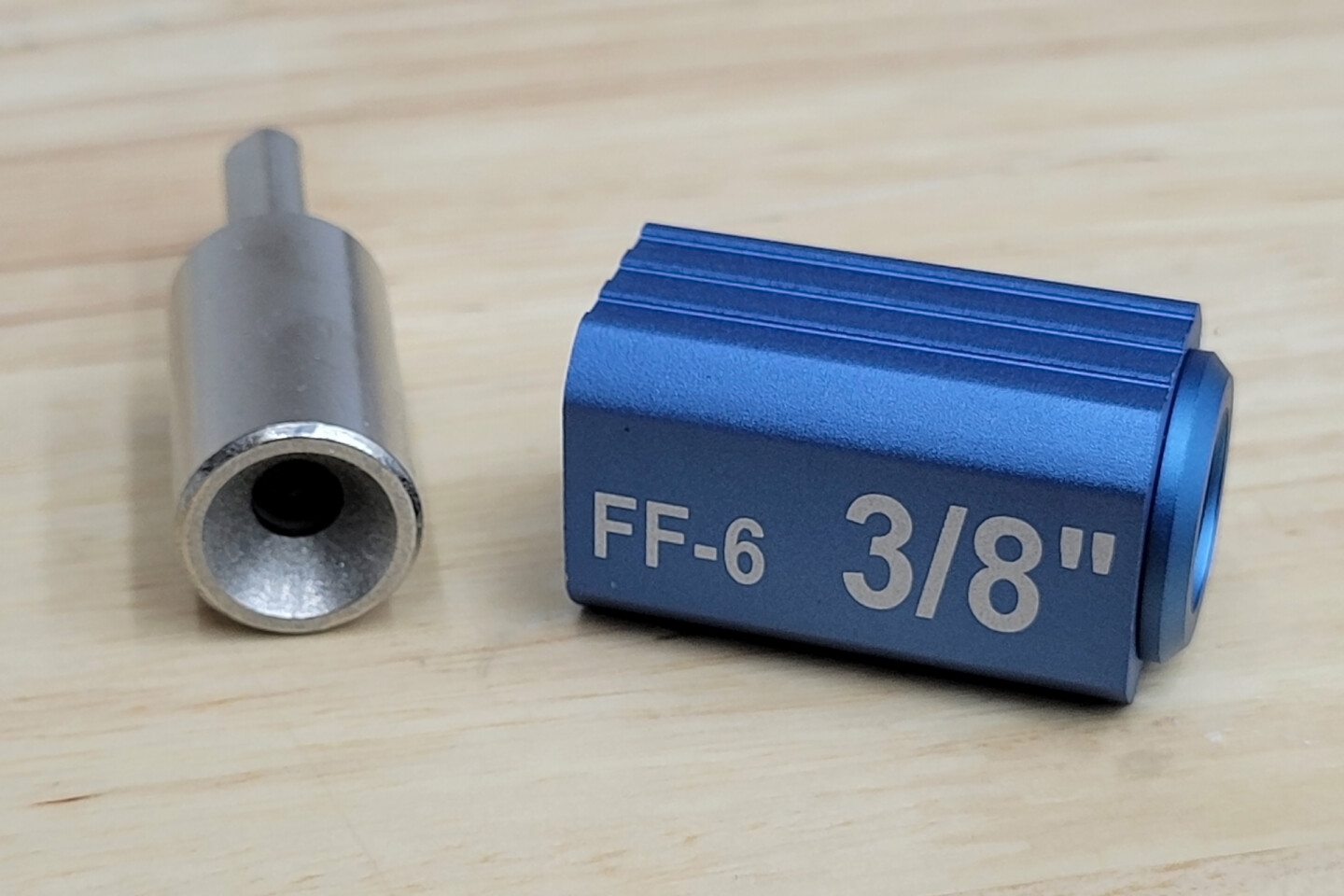

Made specifically for male aluminum or steel 37-degree flare fittings (more than just AN fittings) the Fitting Fixer consists of an alignment sleeve that threads onto the fitting in order to align the flare with the tool, and the driven lapping tool. Machined to a precise 37-degree inverted cone, the lapping tool is coated with diamond dust and fitted to a hexagonal shaft, allowing it to be chucked up in a hand drill or tap handle.

Each Fitting Fixer consists of a conical abrasive cone with a hex mandrel and the alignment sleeve. Both components are specific to a certain fitting size.

Repairing a fitting is a simple affair. Simply thread the fitting into the alignment collar, apply a small amount of lubricant into the abrasive cone, and then insert it into the opposite end of the sleeve. The trick here is to vary the direction of spin, not applying too much pressure for extended periods. This is simply to prevent aluminum build-up in the abrasive cone, as it can be difficult to remove once it clogs the abrasive grit. But, should you clog the abrasive, careful application of oven cleaner or muriatic acid can eliminate the aluminum from the grit.

While the Fitting Fixer is designed to repair fittings that have been knicked, dinged, or otherwise have their mating surface compromised, we discussed another potential use with the Fitting Fixer’s inventor, Dick Raczuk. We’ve noticed that with the influx of inexpensive fittings on the market, the quality of the…

Click Here to Read the Full Original Article at DragzineDragzine…