Certain projects seem to instill anxiety in even the most hardcore enthusiasts. Wiring probably takes top prize in this category, with brake plumbing running a close second.

What makes brake plumbing such a headache? We strongly believe it’s the quality of the tools. Most brake tools are just junk, and junk tools create junk results. It’s just that simple.

We’ve successfully bent up hundreds of brake lines over the years. Our main secret? …

Step 1:

We buy our brake lines two ways. Usually we just buy it in straight sections from our friendly local auto parts store, where it’s generally sold in various lengths ranging from about 12 to 60 inches. If we’re lucky, we can find the exact length we need and avoid having to cut and flare one end. (We’re rarely lucky.)

When we’re tackling a big job, we buy our brake line in bulk coils of 25 or 50 feet. We often choose stainless steel for these projects instead of the plated mild steel that’s available in the straight sections. Not all stainless lines are created equal, so we’ve settled on Classic Tube as our go-to source. Their lines are annealed for easier bendinq.

Step 2:

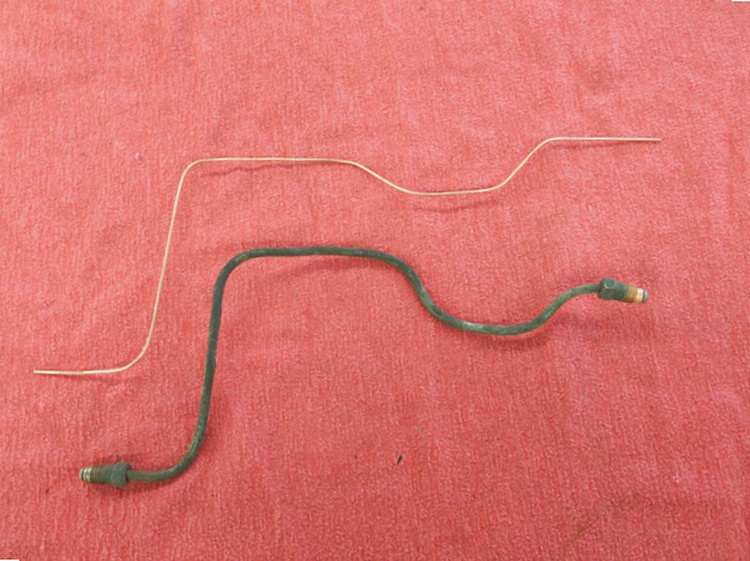

Here’s another big secret: Always work from a pattern. If we have an old line to copy, that’s the easy button. If we don’t, we make our own pattern, usually out of 1/16-inch welding rod.

Step 3:

For this replacement, we started with a 60-inch line sourced from our local NAPA store. Using the old line as a reference, we made our initial bends by hand, working from one end to the other.

Step 4:

This…

Click Here to Read the Full Original Article at Grassroots Motorsports Online Articles…