The process of assembling an engine requires attention to detail from start to finish. How you approach using fasteners and hardware needs just as much thought as any other area of the build. We talked with Bob Florine from ARP to get 10 tips on how to prevent issues with your fasteners and hardware when assembling an engine.

Surgery and engine building have a big thing in common, cleanliness is vital if you want to have a successful outcome. This applies to the fasteners themselves as well as the spot you’re going to be threading the fasteners into. Dirt and debris can prevent the fastener from doing its job or even damage it.

Tip 1

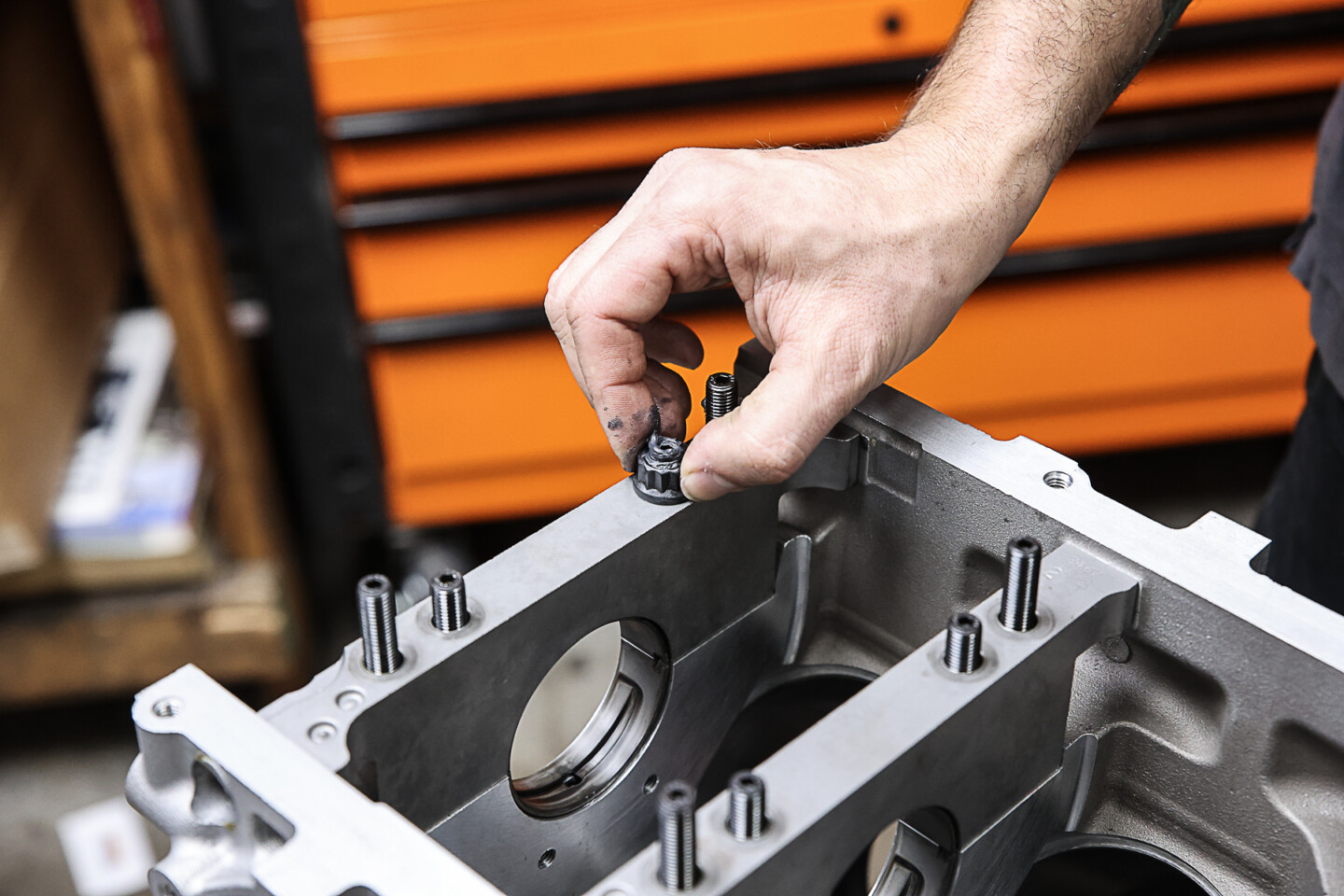

The first tip that Florine brought to us was about making sure the receptor (tapped hole in the block, cylinder head, etc.) is clean and ready. ARP has special “chaser” taps that you can use to clean up a receptor. This chaser tap cleans the threads up without cutting them. A good practice is to blow air into the receptor to remove any dirt or debris that might be inside. You can also spray some brake or carb cleaner inside the hole to aid in the cleaning process.

Tip 2

The next tip Florine provided is that you thoroughly clean the fastener itself. The fasteners might look clean when you pull them out of the package, but it’s always good to take the time and clean them yourself just to be sure. You can use brake cleaner or carb cleaner on the fasteners and then wipe them off with a microfiber towel. A healthy blast of air won’t hurt either according to Bill.

Tip 3

Florine’s third tip covers why it’s so important to lubricate the fastener with the correct product. The lubricant’s job is to “control” the friction each fastener will be exposed to as you tighten it. According to ARP’s website, the friction can inhibit the ability of the fastener to reach its preload during the first few cycles. The correct lubricant will ensure you have preload repeatability and consistency for each fastener.

“ARP’s Ultra-Torque Fastener Lubricant is superior to any oil, moly, or other lubricant you can use on a fastener. It’s laboratory-proven to provide 95-100-percent of the desired preload on the first, and any subsequent pull on the fastener. This is critical to the successful installation of any ARP fastener,” Florinel says.

Tip 4

The fourth tip that Florine provided continues to cover the subject of fastener lubrication. Some people are under the impression that you need to lubricate the underside of…

Click Here to Read the Full Original Article at DragzineDragzine…