Moser Engineering started churning out a wide variety of products in 1986. The company now has a massive catalog of high-performance goodies that has everything from rearends, to suspension parts for numerous vehicles. We got a chance to take a tour of the company’s facility in Portland, Indiana and check out where all the Moser magic happens.

When you enter the Moser facility, you’re greeted by a really cool history lesson. There’s plenty of memorabilia in the lobby, trophies, and pictures from events that tell the Moser story. The next door over from the main lobby is the will-call area where customers can pick up orders. For most people, that’s where the facility tour would stop, but we got to press on and see what goes into making Moser’s various products.

If you need axles in a hurry, Moser has you covered. There’s a room that’s literally nothing but axle blanks of different sizes that are ready to be splined and shipped. According to Moser’s Jeffer Anderson, they can have a set of axles out the door in less than 24 hours for just about any application.

Moser’s shipping and warehouse area is impressive. A dedicated team of hardworking individuals can be found in this area picking orders, packaging parts, and helping to load the trucks each day to get parts on the road. Moser has to keep large volume of parts on the shelf so they can meet customer demand.

Moser has a dedicated area just for rearend and third member assembly. These stations are stocked with all the right specialty tools to assemble anything that Moser sells. The company has developed a set of procedures that helps speed up the process of building each rearend and third member.

Another cool area of Moser’s shop is where all of the custom rearend housings are made. There are racks of blank rearends that can be cut to size for different applications. If you need a custom fabricated rearend, Moser has several workstations that are dedicated to building those parts.

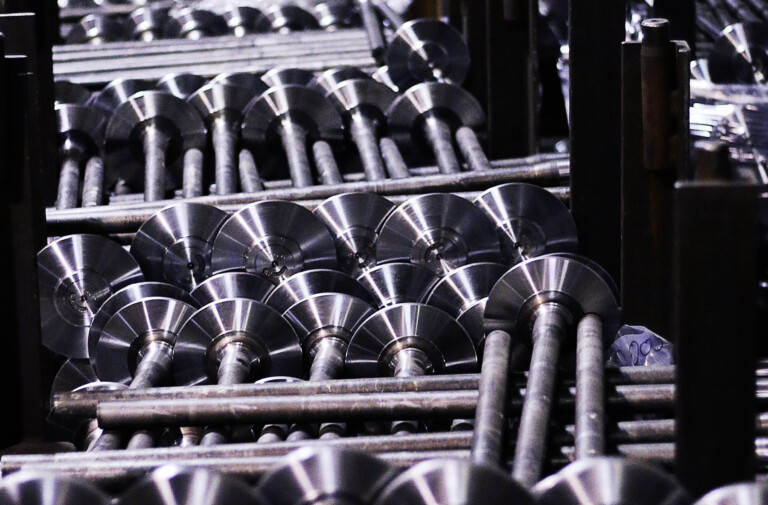

We also learned that anything that has the Moser “M” on it is made right here in the United States. Moser works with a local foundry that casts the majority of its parts. There’s also another building that Moser uses to CNC machine many of its own parts. This allows Moser to maintain a tight grip on the quality of the parts it sells.

You’ll want to watch this entire video on the Dragzine YouTube channel. Jeff Anderson shows us plenty…

Click Here to Read the Full Original Article at DragzineDragzine…