Based out of Morton Grove, Illinois, Strange Engineering has long been known as a leader in drivetrain components, and the company recently released new driveshaft speed sensor kits that utilize a high-precision Hall Effect sensor.

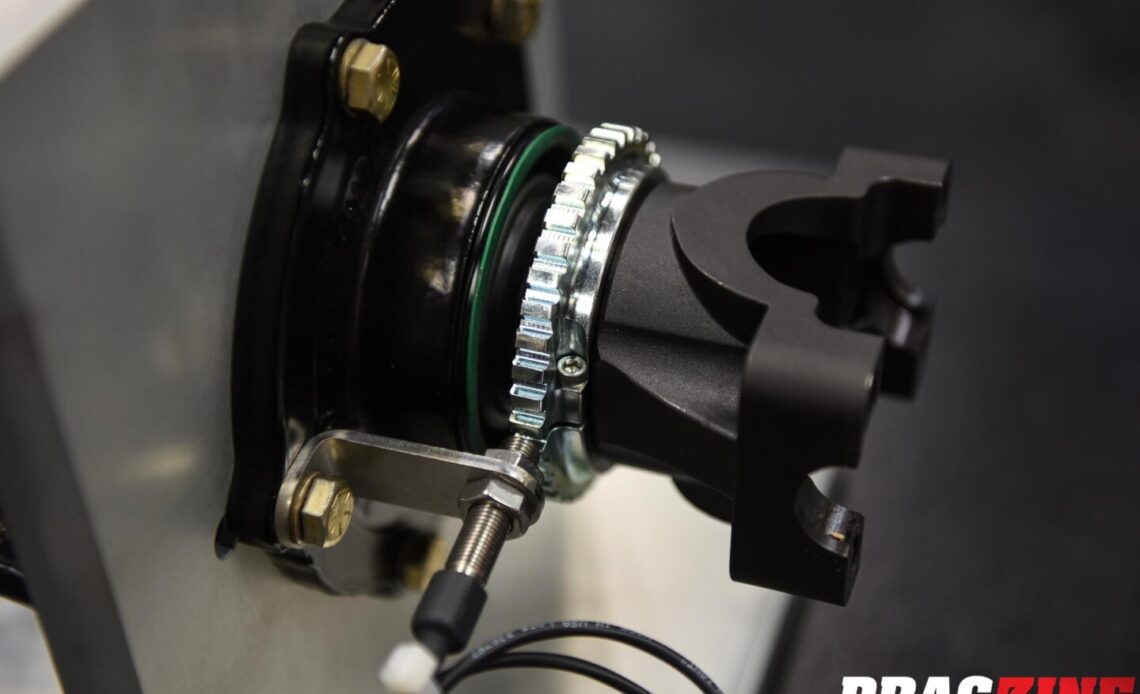

The company currently offers magnetic collars, but it has coupled the Hall Effect sensor with a 40-tooth reluctor ring to deliver a much higher resolution.

“We still offer magnetic collars with 1, 2, 4, and 8 teeth,” says Strange Engineering’s Joe Cascio. “The computers want to see in multiples of eight and 40 was what comfortably fit on the ring and allowed us to keep a good amount of gap between the teeth.”

The driveshaft speed sensor features a stainless steel housing and industry standard 3/8-24 threaded body and requires a 4.5-26-volts of DC power. According to Strange, it has proven to be reliable in Top Fuel cars, arguably the king of vibration-makers, and is made in the USA.

For a stout and reliable connection, Strange Engineering equipped the new driveshaft sensors with a Deutsch DTM plug and includes a mating Deutsch DTM receptacle and pins.

These new sensors are available for Ford 9-inch, Ford 8.8, Dana 60, and Chevy 12-bolt rearends, with the last three requiring the use of Strange Engineering’s chromoly yoke, as it has a specially machined landing for the ring to press onto. Regarding fitments for the 9-inch rearend, Strange offers large stem (2.125-inch) and small stem (1.812-inch) options.

Click Here to Read the Full Original Article at DragzineDragzine…