If you don’t have a lot of experience with automotive wiring, any task task involving this “spaghetti” of electrical conduit can seem intimidating. But when discussing wiring, the cooling system is not normally uttered in the same sentence. However, the cooling system of many cars do require wires, and it all needs to be done correctly. We’re here to help our inexperienced readers understand how to attack the basic wiring of fans as part of a cooling system wiring project.

Fan wiring does not have to be scary; you just need to arm yourself with a little bit of knowledge and the right tools. Thankfully, fans for a cooling system can easily be wired up, but there are a few things you need to keep in mind during the project. We talked with our friends at SPAL to get some basic tips lined up to help you start a cooling system wiring project.

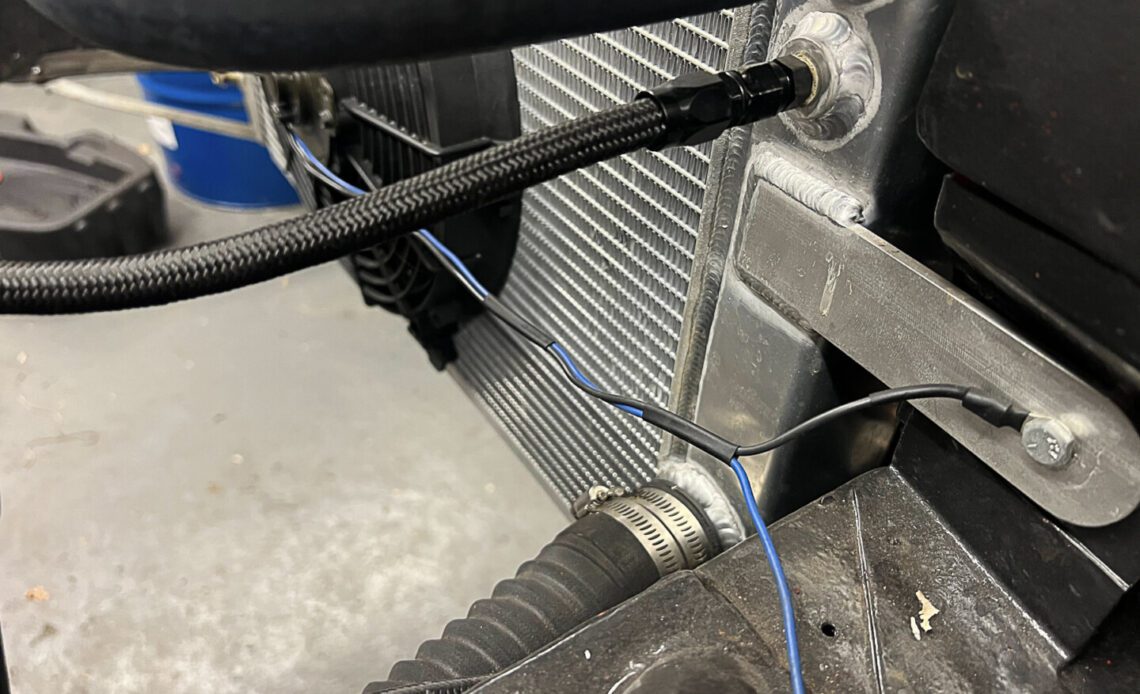

Wiring a cooling fan may seem simple, but there are a lot of ways to mess-up this task if you’re not careful.

The Basics Of What To Do And Not To Do

Your first step should be to come up with a plan that covers where wires will be run before you start snipping and splicing anything. You’ll also want to lay out what materials are required for the project. Another thing you need to do is to make sure you have the right tools. We’ll cover what you’ll need later in the article.

It’s a good practice to keep all your wiring away from heat sources like the exhaust as well as any moving parts under the hood of your vehicle. Make sure you’re routing the wires so they can be properly secured to the vehicle. You don’t want loose wires running amok. It’s important to secure the wires so they don’t get in the way when you’re working on the vehicle or become damaged. If the wires aren’t secured and laid out neatly, it can make troubleshooting difficult if there’s ever an issue.

The gauge of the wire that you use in your cooling system wiring harness is very important. SPAL’s Greg Goeders explains why you need to make sure you’ve got the right size wiring running to your cooling fan.

“You have to make sure the wires used to power the fan are ample sized for the electrical load the fan is expecting to see. Wires, just like fuses, have a time rating during each loading condition. If the amperage is high, the time the wire can handle the load will be very short. If the amperage is properly aligned to the wire size, the wire can handle the load indefinitely. Making sure the wire can handle both the…

Click Here to Read the Full Original Article at DragzineDragzine…